Torque converters are like a magician’s black box. We basically know what’s going on, but we’re not really sure how it is doing, what it is doing. The torque converter [1] plays a critical role in how any truck performs. The wrong converter can make the truck feel like it has no power, gets horrible fuel economy, and it is as slow as molasses. On the flip side, the right converter can make all the difference in the world. Choose wisely, and the truck will perform well, it will be easy to light the turbocharger, and fuel economy will be optimized.

The torque converter is the first and perhaps the most important link between the engine’s power and the ground. Torque converters work the same, no matter what type of application it is in — whether it’s powered by gas or diesel. However, tuning them to each application is as different as night and day. But before we get into how to choose the right torque converter for your application, it is important to understand the components that make up this magical fluid coupler.

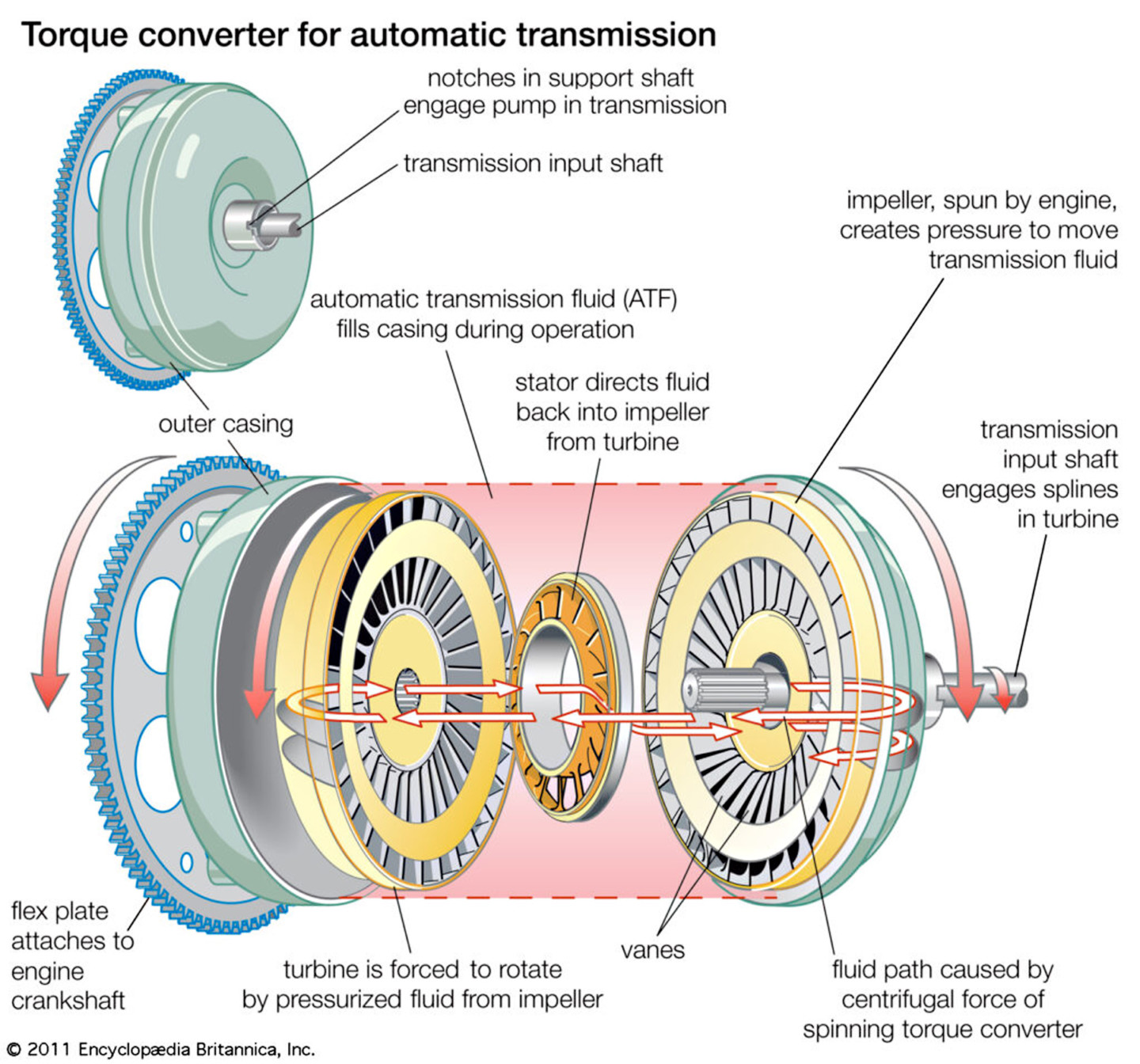

Front cover (the pump):

The pump is comprised of a series of veins/fins that are welded to the cover portion that slides into the transmission. Since it is part of (affixed to) the housing that is bolted to the flywheel/flexplate, this outer housing turns at the same speed as the engine at all times. The veins attached to the inside of the cover take the transmission fluid in the center of the torque converter and sling it to the outside, across to the turbine.

Turbine:

The turbine’s center section is splined and rides on the transmission’s input shaft. The turbine has veins that face the opposite direction of those on the front cover. As the fluid is slung from the front cover into the turbine, it creates pressure in a clockwise direction. Once the pressure is high enough, it starts to spin the turbine and sends power to the transmission. (Think of this as two electric fans facing one another. If one fan is turned on, the air it pushes will start to spin the fan that isn’t on.) The fluid that is slung from the front cover to the turbine is then redirected back to the center of the pump through the stator.

Stator:

The stator is directly responsible for the torque converter’s characteristics of operation. As the fluid leaves the turbine housing, it is directed back to the stator vanes. These vanes then direct the fluid to the front cover.

The position of the vanes is a major influence on the torque converter’s stall speed, how much load is put on the engine, and how much torque multiplication the torque converter imparts. Like the turbine housing, the stator is also mounted on the transmission’s stator support shaft and is positioned between the turbine housing and the front cover.

Clutches:

Behind the turbine housing are the clutches and plates. Depending on the builder of the torque converter, the number of clutches and plates will vary. Many factory torque converters for gasoline applications have only one clutch, while most OEM diesel applications utilize a minimum of three clutches. The clutches apply the clamping pressure that locks the back cover to the turbine housing. This makes the torque converter fully locked and the transmission’s input shaft will spin at engine RPM.

[5]

[5]The clutches and friction plates are what received the fluid pressure to apply the movement of the transmission internals.

Back Cover:

The back cover is the final piece in the torque converter assembly. This is where the torque converter physically bolts to the flywheel. On the inside of this portion of the cover is the surface area for the last clutch to press against. The inside of the cover is what the clutch plates ride against. The outside of the back cover is welded to the front cover in most applications. In some extreme race applications, the back cover is bolted to the front cover. Now that you have an idea of the basic components that make up a torque converter let’s talk about the terms that describe the characteristics of a torque converter.

[6]

[6]The back cover. The fluid pressure developed as the torque converter spins applies pressure to the clutches which in turn apply pressure to the back cover, turning the transmission internals.

Lock Up:

When you hear the term lock up, this occurs when the clutches in the converter are engaged. When the torque converter is “locked up”, the transmission’s input shaft will spin at engine RPM.

Stall:

Torque converter stall is the point at which the converter freely spins before engaging. Getting past “stall” means the engine has reached a certain RPM and the torque converter internals have built up so much pressure against the transmission that the input shaft begins to spin, causing vehicle movement. One way to approximately determine the stall speed of your torque converter is to put your vehicle in gear, hold the brake and slowly apply the accelerator pedal. When you reach the RPM point at which the car wants to move, you have found stall speed. The stall is not the point at which the tires break loose, but when the engine wants to make the car or truck move.

Tight Converter Or Low Stall:

A tight converter is when the engine cannot build enough RPM to allow the turbo to start to spool up. This is most apparent in trucks used at the drag strip. The next time you’re watching a diesel drag race, if you hear or see a truck take forever to build engine RPM, it’s because the engine is fighting the torque converter and cannot spin fast enough to create the heat and volume of air needed to get the turbo spinning properly.

Loose Converter or High Stall:

A loose converter is when an engine can “rev to the moon” before anything happens. When this occurs, the converter is not producing enough resistance to hold the engine. When driving down the road with a converter that is too loose, when you apply the accelerator pedal, if the engine will rev up, but it takes a while for the vehicle to increase speed, this means you have a torque converter that is too loose. A loose converter can create excess heat and wear out quickly. It will also hurt fuel economy.

What Makes Each Converter Stall Differently?

Stator design is usually what dictates stall speed. The difference between a converter that has a low stall or a high stall, is dictated by the angle, pitch, length, and position of the fins

So, how do you know what to ask or look for when choosing a converter? We went to Sun Coast Transmissions and talked to Ron Wolverton to get some professional insight.

“Without looking inside of a converter it is hard to know what you are getting,” says Wolverton. “Price is one indicator. It is hard to add billet parts, heat-treated splines, and extra clutches at a discounted price.”

Another aspect to be aware of is the “one size fits all torque converter. Wolverton mentioned that many people are using a Dodge-style stator in all of their applications. “that just doesn’t work all the time,” he continues. “The Fords are a great example of that. They are close to the same displacement (6.0 vs 5.9), but the Ford stators and Dodge stators are totally different. The Ford’s love to rev and if anything, are close to a gasoline style stator, while the Dodge engines love to be loaded and we use a very aggressive stator on them.”

In addition, to watching out for one size fits all and value-priced torque converters, check to see if the company you are purchasing from can fine-tune and make the appropriate adjustments for your exact application. Many companies are rebuilding and modifying factory converters. The factory converters are designed for the 350 to 400 horsepower that OEs rate the engines. With the addition of chips/modules, air intakes, exhaust, turbochargers, injectors, and don’t forget nitrous, many people are pushing 500 to 800 horsepower in their daily drivers. A custom torque converter is the only way to get the proper stall speed and to be able to load the engine enough to get the most out of it.

Also, when talking to an aftermarket converter supplier, ask about refreshing and changing the converter as you continue to build/modify your truck. Some companies, like Sun Coast Transmissions, offer an NDR (non-defective return). What this means is, they will disassemble the converter, clean it up, and change it to meet the new requirements of the engine for a fee less than the purchase of a new converter.

So, whether you are about to spend a few thousand dollars on a new transmission or have been building your truck for a while and need a new torque converter, calling around and asking the right questions can make all the difference.