[1]Generally speaking, it is accepted that heat is the enemy of engines, but what if we told you this is not always true? Heat is energy, and in an internal combustion engine, heat represents a large portion of lost horsepower, but it can also be harnessed for your benefit. We worked with Heatshield Products [2] to test some common heat barrier applications and found out how heat can be harnessed for horsepower.

[1]Generally speaking, it is accepted that heat is the enemy of engines, but what if we told you this is not always true? Heat is energy, and in an internal combustion engine, heat represents a large portion of lost horsepower, but it can also be harnessed for your benefit. We worked with Heatshield Products [2] to test some common heat barrier applications and found out how heat can be harnessed for horsepower.

Why Heat Is Bad

Heat is a byproduct of combustion and friction. The engine takes fuel and turns it into two types of energy — kinetic energy, whereby the engine generates rotational force and ultimately drives the wheels; and thermal energy, by-which heat is generated though compression, combustion, and friction. The latter byproduct contributes to the wear, and fatigue your engine experiences over a lifetime.

Ever wonder why a dyno graph stops climbing after a certain peak RPM? When the detriments of heat and friction become greater than the engine’s ability to flow, efficiency drops. The higher RPM an engine runs the more friction it generates, exceeding the optimal compromise between friction and RPM results in friction winning. Heat also corresponds to density when talking about air charge. It is common knowledge that the more air and fuel you can force into an engine, the more power it will output, to a point. Hot air is less dense than cold air and must be delivered to the engine with a leaner fuel mixture. Less air and fuel equals less power.

Why Heat Can Be Good

The beneficial effects of heat are often overlooked by automotive enthusiasts. The most important of which is the removal of another product of combustion, water. Yes, good old H2O is a byproduct of combustion. When you burn fuel, water is generated and can leach into oil. It sits on ferrous surfaces and generally accelerates the wear of your engine. If an engine is not allowed to come up to full running temperature to where the water can be boiled out of the oil, it will collect and begin to wreak havoc.

Foaming oil, rusting bottom end components, and scaly cylinder walls are all side effects of engine oil contaminated with water. Another benefit of heat is unique to the turbocharger crowd, when hot air expands in volume. Try this; blow up a ballon and put it in the freezer for a while. When the warm air you filled it with cools, the diameter of the ballon will shrink. The physics of hot gasses expanding is used to great effect in turbocharging. If exhaust is used to drive the turbine while it is at its hottest, such as close to the exit from the engine, it will effectively have more volume and velocity as the hot gasses try to expand in the confined space of a header. This harnessing of heat can be used to reduce turbo spool and lag and maximize the efficiency of turbocharged applications.

Heatshield Products Can Be Applied To Both Insulate And Repel Heat

We decided to take a typical diesel truck and apply an assortment of Heatshield Products [4] to see what gains can be achieved with a simple modification. The truck used was a 2008, Dodge 2500 with a 6.7-liter Cummins turbo-diesel, featured an Edge Programmer, and is used primarily as a tow vehicle to get toys to the desert and lake. A rig we can all relate to, we wanted to show a few Heatshield applications anyone can do, and will net gains without sacrificing reliability fuel economy.

Different Kinds Of Insulation

Tape: Heatshield tape is the thinest and narrowest product for wrapping small engine parts to protect them from heat. Electrical looms, fuel lines, brake lines, and other such applications can benefit from this heat-reflective tape.

Armor: A heavy-duty insulation material best-suited to the exhaust system and emissions equipment of cars and trucks. Two pleated metal layers are separated by a thin liner. The resulting shield is capable of withstanding 1800 degrees F. According to Steve Heyes of Heatshield Products, the insulation “is our exclusive BioCool insulation. It is a bio-soluble silica. It’s not itchy, has limited smoke and odor when it is heat cycled. Totally safe to work around, no nasty respiratory fibers like some of the import ceramics and fiberglass products.”

[7]

[7]We used Heatshield Armor to insulate the Dodge’s exhaust between the cat and the Diesel Particulate Filter (DPF).

Sleeve: Heatshield’s products are sewn into a tube to fully enclose and protect the lines. Air conditioning hoses, wiring, coolant, oil, and intake lines can all benefit from sleeve heat shields. Heyes explained that “sleevings for the air intake tubes, we use a high grade S fiberglass, that allows us to give a mirror-like finish, makes it more flexible and more reflective than other products.”

Mat: Heatshield Products’ Mat is a wide, thin layer of reflective material backed with insulating fiber cloth. Locations for this product include large open surfaces, floor pans, under hoods, firewalls, around airboxes and other such applications. We chose to wrap the air charge to intercooler pipe with reflective mat. The result will be a cooler air charge to the intercooler, and ultimately to the engine.

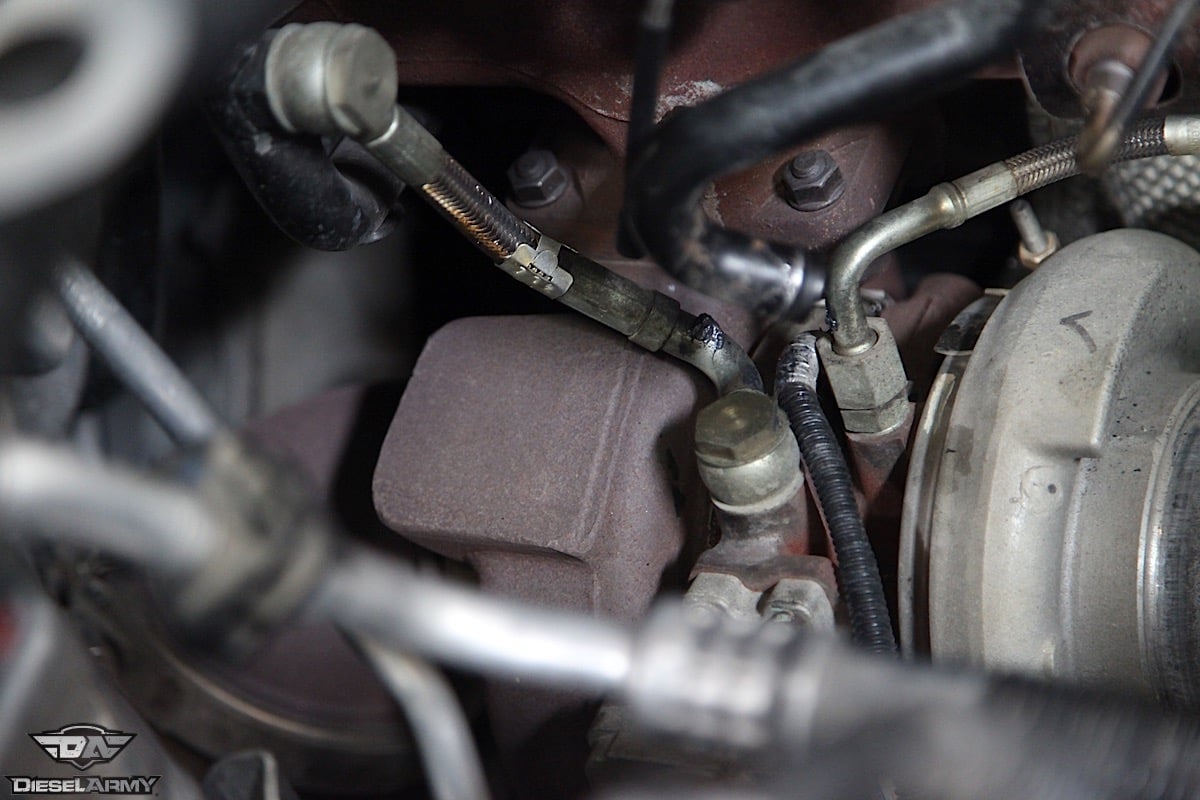

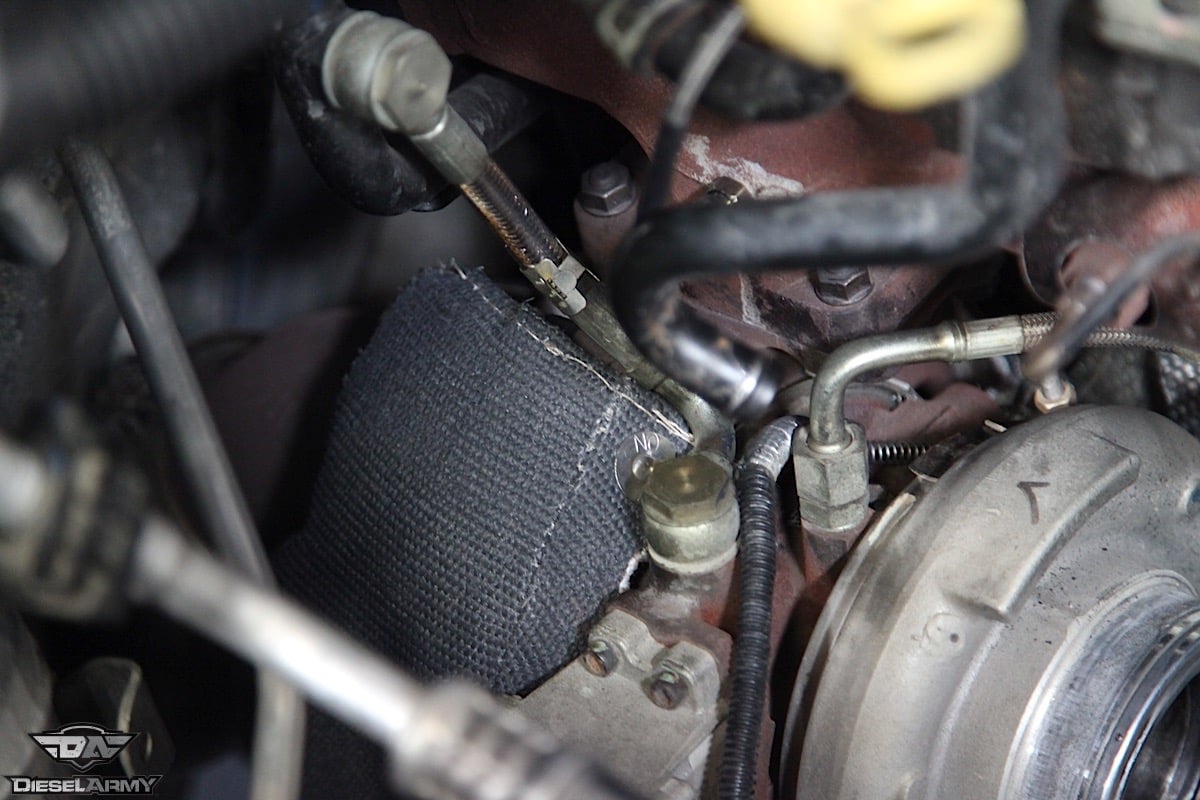

Turbo Blankets: Turbo blankets are one of the few insulation modifications specifically designed to keep heat in as a performance improvement. By wrapping the turbine side of a turbocharger in a thick insulated blanket, more heat will be retained to promote faster spool and less lag. By keeping more heat inside the turbo, temperatures under the hood will be lower and less heat will affect the induction, cooling, electrical, or other systems.

Wrapping the turbo on this Dodge was the most involved procedure of our heat shielding. Accessing the turbine side of the turbo required some disassembly of the induction system but the end results were well worth it.

Results:

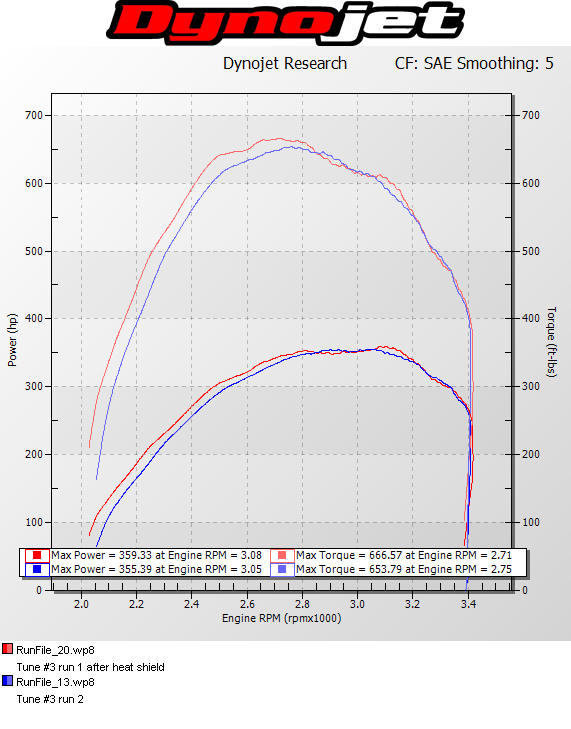

The baseline readings netted 355.39 horsepower, and 653.79 lb -t of torque. With all the Heatshield Products installed, the resulting power and torque curves show a 3.94 horsepower gain, and 12.78 lb-ft of torque over the baseline run! In a daily driver application — where a truck may be run for an extended time down the highway, these products may help reduce heat soak. As hot under-hood components radiate heat to surrounding components temperatures in air, fuel, electronics, coolant, and oil rise. By reducing heat soak one can reduce the affected systems, and possibly increase their lifespan, and effectiveness.  [13]

[13]

Who Needs Heat Shielding?

Heatshield Products produces products to reflect and insulate heat for applications across many markets. Whether you are looking for every edge on your race car, or need to keep things cool in an industrial application, there is a product to fit the need. Heyes explained to us, “Some of our products start off as race car products, then work their way into other market segments. The Armor products were actually developed for a local trash company who was one of the first to hit these ridiculous new emission standards put on diesels.They needed something that worked better than exhaust wrap for the higher heat of the DPF’s, and something that was more rugged. Out of their need the Heatshield Armor was born.”

They needed something that worked better than exhaust wrap for the higher heat of the DPF’s, and something that was more rugged. Out of their need the Heatshield Armor was born. -Steve Heyes, Heatshield Products

Heyes has had a broad cross-section of test applications to back up his products. We asked him what sort of research and development was conducted, such as lab testing and real world applications of the products. “On the industrial insulation, you do lab testing, then we always like to do some real world testing. Labs can yield great results, but you change a few environmental application conditions and some of those ratings go right out the window,” he said.

Heyes values the feedback of top customers to help develop new products. “One of my favorite testing teams are the guys over at Danzio Performance Engineering. If we can keep them cool in their twin turbo trophy truck in 110 degree F plus heat, we know we have a product that is a winner. But, we will work with road race teams, rally, Trans Am, etc. We look for guys pushing the limits, and those that are good about getting us data.”

Conclusions

Our experience with Heatshield Products proved there are several benefits to heat management. Our dyno baseline and improvement showed that keeping heat in where it’s needed, and out of where it is harmful, is a viable and easy means of maximizing efficiency, and an un-pursued avenue for horsepower that puts no additional strain on the engine.

Free horsepower is a myth, but — in the case of heatshielding, the relative price is low for the return. As heat becomes more and more extreme in high-performance applications, one can expect the gains to be respectively more noticeable. Our test vehicle was a mild sample of heat management. The potential returns on a full race application would no doubt provide interesting data. We look forward to seeing the developments and improvements Heatshield Products can make for vehicles of all types. For more information about the products offered, visit Heatshield Products [2].