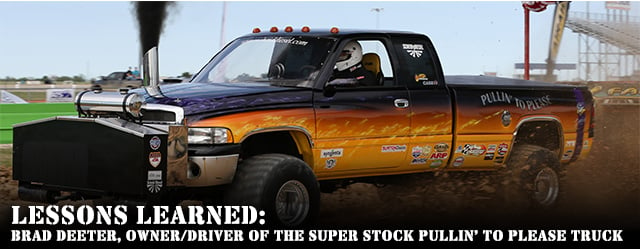

In this month’s segment of Lessons Learned, Diesel Army caught up with Brad Deeter, the 2013 NHRDA National Champion [2]. In the last couple of years, Deeter has rocketed to success and has stood on the podium consistently enough to win the National Championship.

Background:

Brad Deeter started out at an early age working in the fields at Deeter Farms. Later, as Deeter Farms expanded into the construction business, Deeter found himself wearing a lot of hats. In 2006, he graduated Rocky Grove High School and headed off to Erie, PA to attend Penn State University. Over the next four years, he earned his Mechanical Engineering degree while juggling quite a load at home.

When Deeter finished his sophomore year, Deeter Farms Construction moved to Washington, Pennsylvania, thanks to the booming oil field business. When they moved, they had three trucks and just a few pieces of machinery. So, Deeter found himself working very long hours over the summer to help out and found it hard to leave to go back to school when the family business really needed him. Whenever possible, Deeter would make the four hour trip to Washington, to support the family business. In 2010, he earned his degree and went straight back to work at Deeter Farms. Since then, they have doubled in size every year and currently employ over 60 people. They are running 30 trucks and have 25 pieces of heavy equipment.

Deeter is the operations superintendent and with a position like that, doesn’t come without a lot of sacrifice. When Deeter isn’t on the track, he is out at a worksite making sure that business is handled. Anyone who is this dedicated and successful at work and at play, must have a solid foundation of knowledge and a good basis to make informed decisions. So who better to line up as our next Lessons Learned feature. We sat down with Deeter and asked him to outline five of the biggest lessons he has learned through the years.

- Lesson 1: Start with a good foundation.

- Lesson 2: Choosing your parts wisely.

- Lesson 3: It’s a driver’s game.

- Lesson 4: It isn’t as easy as I thought it would be – be prepared.

- Lesson 5: Look toward the future.

Lesson 1 – “Start with a good foundation.”

Deeter’s Story

The first time Deeter decided to hook up to a sled, was during the summer between his junior and senior year of high school. “For our Senior Project, we built a sled pulling truck. It was a ton of fun and we even managed to get an A,” shared Deeter.

[5]

[5]Brad Deeter’s original sled pulling truck was a 1997 Dodge 3500 that was one of their farm trucks.

When they decided to build a sled puller, they looked around at what was successful and started with a 1997 Dodge 3500 Dually (farm truck from Deeter’s Farm). In 2005, horsepower wasn’t where it is today, so Deeter had some fuel plate work done, injectors, added ladder bars and installed a South Bend clutch [6]. He pulled in the “Work Stock” class for that first year.

The following year, Deeter stepped up to run in the “Unlimited Single” class. He built an engine and set the truck up for a 3.0 charger. With how busy the family business was and with moving to go to Penn State, he only ran the truck three times before he decided to stop pulling. “Looking back, it was a good time to step away. Right about then, the horsepower really started to jump up and it would have been really expensive to stay competitive over the next few years,” commented Deeter.

When Deeter finished up school and earned his Bachelor’s degree, he knew he wanted to get back into pulling and started to look for a proven truck. He ended up purchasing Faith Miller’s old truck, which had been a proven competitor in the past.

[7]

[7]Deeter has been extremely consistent throughout the year. He hasn’t always won, but placing high enough consistently yielded him the 2013 NHRDA National Championship.

Lesson 2 – “Choosing your parts wisely.”

Deeter’s Story:

Once Deeter had the new truck it was time to update it and get it ready for the season. When Deteer picked up the truck, it had been set up for the old DHRA 3.2 rules (DHRA was the Diesel Hot Rod Association which used to be the only diesel organization nationally). So, in order to be ready for the Super Stock Class [8] Deeter had to tear a lot of the truck down and rebuild.

Here is where choosing the parts wisely comes into play. Deeter knew that he would be making 20 to 35 pulls a year. This means he is away from home 20 weeks of the year. “The people that you run with, pretty much become your extended family,” says Deeter. “Not only are they willing to help you out when you need it, but if something breaks, they are the first people there to offer to help,” he continues.

[9]

[9]A big key to success for Deeter is to start with a solid base vehicle. He ended up purchasing Faith Miller’s pulling truck. From there, they got to work and updated it and started pulling right away. This was not only much quicker than building a truck from scratch, but most of the chassis tuning was already done.

So, if it is a choice between two companies’ parts that will work, Deeter looks to see what the guys are running, and he goes with the group choice. Even though many of the guys are running similar parts, they are still very competitive pulling against each other on the track. Even as competitors, they still pride themselves on working together to raise the level of the sport. After every pull, they all talk about what they saw, felt, and what was going on. They will even swap data logging files and discuss what they are trying – it is this type of camaraderie that really illustrates the “family” type bond of Diesel Pulling compared to some other racing and competitive automotive sports out there.

According to Deeter, “I wouldn’t want to run if these guys weren’t there to give me a run for my money. But, on the flip side I would never think of not helping them perform to their best. I wouldn’t want to win if I didn’t know the guys on the track in my class weren’t bringing their very best.”

Lesson 3 – “It’s a drivers’ game.”

Deeter’s Story:

Deeter was quick to point out that everyone has a similar set up and amount of horsepower. “Horsepower will show in the beginning, but pulling is really 90% of the guy in the cab running the throttle and clutch,” state Deeter. We dove into the meaning behind this statement to understand this lesson. It is a drivers’ game and how you play it depends on where you will place.

[10]

[10]Believe it or not, but these huge Dick Cepek Giant Puller tires (34x18R15) are now a limiting factor for the pullers. They are putting down more power than these tires can handle, according to Deeter.

One of the key elements is building your knowledge base on the track where you will be pulling. Reading the track is one of the key points that Deeter stressed during our interview. Here’s the key points he mentioned that should be considered:

- Check what number you are running in line. If you are not hooking in the number one or two spots you need to look for a path that is off set by the damage of the previous trucks.

“Immediately, if I am not running in the one or two spot, my team begins scouting where all of the other trucks are running to help me determine the cleanest run path for my pull,” Deeter continued.

- Trucks like a harder packed track, “If I can stick a probe in the ground 6 inches, then I know I don’t want to run in that location as it’s too soft,” continued Deeter. Trucks want a pretty firm clay and Deeter likes to take the clay in his hand and see how it sticks together and how fast it dries out to determine the quality of the soil where he will be running.

[11]

[11]Deeter is one of the few pullers remaining in Super Street that run compounds instead of triples. These compounds are proven and they are what the engine was originally built for.

“These tips won’t get you 30 feet ahead of everyone but it will put you 30 feet back of them if you’re not paying attention,” continued Deeter.

When it comes to being ready for a pull and getting focused family is also key. Deeter often will drive to an event; wait all day for his “12-seconds of fame.” Then have to drive all night just to get home by sunrise, to head out for a long 14-hour work day.

For Deeter it is the people that help him that make all the difference in the world. This includes, not only the support of his pit crew (brother Josh, sister-in-law-Kelly and his wife Allison) but, also, his pulling family. While there are multiple camps (the Scheid [12] group and Haisley [13] group), each camp is extremely tight with each other and very helpful and friendly to the others within other camps.

Lesson 4 – “It isn’t as easy as I thought it would be – be prepared.”

Deeter’s Story:

When talking with Deeter he said that one of things that he found most surprising was the complexity of what all was involved at this level. Even when they are not pulling there is constant maintenance to be done from oil changes to the adjustment of the clutch every four runs, etc. Then there is all that goes into getting to the pull, from packing the trailer to making the ice for the truck to use at the pull. At any given race, Deeter goes through more than 100 pounds of ice a night. So much ice that not only do they have a refrigerator in the trailer but he even bought an extra ice maker for the house to get ready for each event.

There is a consistent amount of work that has to be done at the track and at home, just for that infamous 12 seconds of fame.

Deeter and his team have developed a check list that they use to prepare for each race in advance both upon loading for the trip and unloading at the track. When they arrive at the track the aim is to be there at least four hours prior to race time to be sure everything has been checked and is good to go. “It’s important to be here and ready at least two hours before it’s time to run. You never want to get that last minute rush to race feeling, that’s when major mistakes and failures happen,” continued Deeter.

One tip that Deeter was sure to mention was to make sure that the headsets were charged at each race. He pointed out that communication with his team was a key element in his success and if the headset is not working it’s near impossible to communicate when on the track.

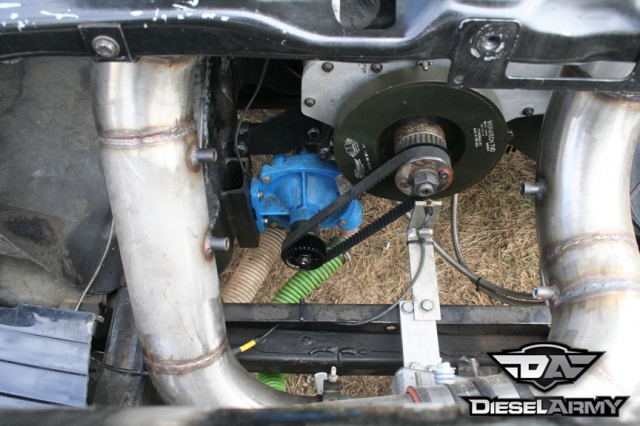

[14]

[14]This engine driven water pump actually out performs the 4 high volume bilge pump Deeter was previously running.

Then there’s the strategy of preparing for the pull. “It’s important that you have a game plan going into the night. You need to know exactly what to do as far as launching the truck, what RPM do you need to get up to, how you want to come off the clutch, what place on the track you want to run and then get properly staged and prepare to come out hard and ready for those few seconds that all this work has lead up to,” Deeter continued.

“When it’s time to pull, I go through the check list to make sure we are ready and then it’s like tunnel vision sets in. No matter what else is going on it just all fades away. Recently, I was at a pull where a semi-truck caught fire during my run. I’m finished and being unhooked and everyone is hooping and hollering about the fire including my wife and I never even noticed. It wasn’t until I got back to the pits and everyone told me what happened that I took notice of it,” said Deeter.

Lesson 5 – “Look toward the future.”

Deeter’s Story:

In an ever-changing sport like sled pulling, it’s more important than ever to keep your eye on the prize but also to continually look toward the future. Deeter is doing just that in a number of ways. The first way is by being an ambassador for the sport and helping it grow. He talks it up everywhere he goes trying to garner more interest and is usually met with a favorable response.

One wish he would have to help the sport grow, would be to unify the classes and rules across all of the pulling leagues both regionally and nationally. “For the sport to really take off and people to justify going out and spending $50,000 on a 2.6 truck to be competitive everyone really needs to sit down as a sport and set up the same classes and rules across the board. It’s really hard right now, knowing that you have so much invested and in a year it could all change or knowing that you are limited to participating with only the association you built your truck for,” shared Deeter. “It has been getting better over the past couple of years, but there is still a long ways to go,” he continued.

The new pulling truck is coming together quite rapidly and is anticipated to debut in 2014 with an entirely new powertrain. Stay tuned as we plan on featuring this one when it debuts. [15]

[15]

Deeter, also, keeps an eye on where the sport is going and what is needed to remain a competitor. With that in mind, he is in the process of building a complete tube chassis truck. Working with Dan Scheid [12] he is building a competitive rig to be a lot lighter and more powerful than his current setup. One of the biggest reasons to build a tube chassis truck for Deeter was not only to drop some of the extra weight and get the advantage of the additional flex in the chassis but also to install a tilt-body. In his current truck, when something breaks like an injection pump, it’s a nightmare for him to hang over the front bumper trying to maneuver a 60 pound pump strategically into place. With the new truck and a tilt-body, he will have easy access to everything.

“I came to the realization that you almost have to have a tube chassis to be competitive these days and I’m a very competitive person that’s just how I am. If I’m going to do something, I’m going to do it right and this will help me do just that,” continued Deeter.

Final Thoughts

“There’s a lot more to this sport than just dragging your truck through the dirt. Pulling for those 12 seconds and passing that 300 foot mark make it all worth it to us. In the end, it’s the preparation and the people involved that will make or break a great pull and event. We’re lucky to have really great people on our team, great people to compete with and great people running these events. I can’t wait to see how this sport grows and evolves over the next few years.”

“In addition to my regular family that I owe a huge debt of gratitude to, I wanted to say how much I appreciate all of the hard work and parts from Brad Ingram and Kent Crowder with Scheid Diesel [12]. These guys are first class and truly family!” Deeter concluded. We can’t wait to see what’s next out of the Deeter camp, check back often for future updates on his latest build right here at Diesel Army!