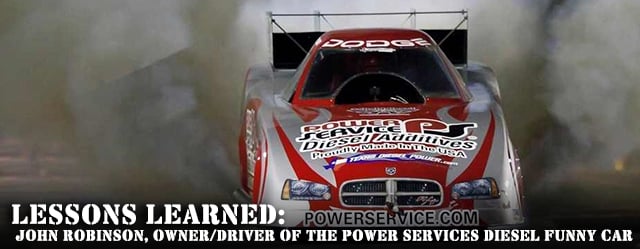

“The Beauty Of Racing, Is The Journey Of Getting There” – Those words are spoken by a man who has had quite a journey over the years. Diesel Army recently had the opportunity to sit down and speak with John Robinson, Owner of Texas Diesel Power [2] and driver of the World’s first diesel-powered funny car, about his journey over the years for our Lessons Learned monthly segment. Each month we will take a prominent racer and interview them to put them “on the spot” so to say about some of their challenges and lessons they’ve learned along the way.

Sharing these lessons with our readers will provide valuable insight and real-world challenges that these professionals face throughout their careers. Many of us have learned our own lessons in both life and in racing, so stay tuned for plenty more, right here on DA.

A Little Background

Driver Profile: John Robinson

- Hometown: Weatherford, Texas

- Occupation: Owner of Texas Diesel Power

- Years Racing: Eight (professional)

- Best ET: 7.40

- Best Speed: 188 mph

- Website: www.TexasDieselPower.com [2]

John Robinson started out in the mid ’80s busting tires and changing oil on a fleet of Kenworth trucks. It wasn’t long before he worked his way into the shop and started learning the diesel trade. Over the next 15 years or so, he worked at a few different shops on a variety of over the road trucks. He had owned his own business for about 10 years when an opportunity came along that was too good to pass up. Well, as the old saying goes, what sounds too good to be true usually is, and Robinson decided it was time to follow his passion.

“I had been wanting to jump into the performance market for a few years and this was the right time,” continues Robinson. So, in 2000, Texas Diesel Power became a reality. Today, they operate out of downtown Weatherford, Texas in a 6,000 square foot shop with nine loyal employees. “We really focus on honesty and doing the right thing, even when no one is looking,” says Robinson.

New Years Eve (2005), Robinson headed out to go look at a car. “My wife called me in the afternoon and asked where I was and wanted to make sure I knew about the party that night. I told her I had to go look at a car and I was probably going to be late. I pulled up a little after midnight with a 40-foot trailer and a dragster in tow. She had no idea I was looking at going racing and boy was that one upset mamma!”

So, after learning more on Robinson’s background, we knew he would have some great tips for us so we asked him to be our first victim for this monthly series and to share some of the lessons learned throughout his racing career.

- Lesson 1: Going racing doesn’t have to cost hundreds of thousands of dollars.

- Lesson 2: Spend money on the good parts, don’t just hope that something will work.

- Lesson 3: Buy from people who can help you if you have issues down the road.

- Lesson 4: Comic relief is important to help focus on the task at hand.

- Lesson 5: Get in bed with quality sponsors and don’t bite the hand that feeds you.

Lesson 1 – “Going racing doesn’t have to cost hundreds of thousands of dollars.”

Robinson’s Story

[5]

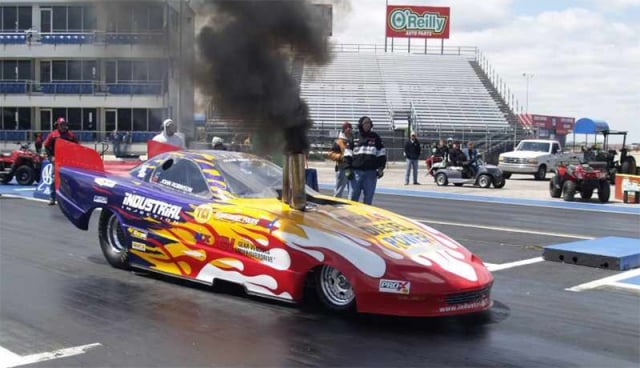

[5]Scott Bentz (far lane) lines up against Robinson (near lane) in 2007. Bentz and Robinson were both running 5.9L Cummins.

“When we got started, there were two dragsters running; Scott Bentz and Dan Scheid,” says Robinson. As far as Robinson was considered it was simple math. If he had a lighter vehicle he would go faster and a rail was easier to work on. Robinson went down to the bank and got a $25,000 loan. With that, he bought the trailer, dragster, and the parts needed to put it together.

To power the rail, Robinson kept with the budget approach and pulled the engine out of a 250,000-mile cement truck. To give the rail the power he needed, they opted to use a 12mm p-pump, injectors and compounds. Mating up to the engine was a 47RE out of a 2500 pick that was only mildly built up.

“We were so green and had no idea what we were doing. One night we went to the track to test the car. We just wanted to see if it would go down the track. So, I had one of the guys buy a helmet and we showed up. The track officials wouldn’t even let us on the track without a full race suit. I told him, we aren’t going fast. I just want to see if we can make her go,” Robinson chuckled. Robinson ended up borrowing a suit from another racer and they made a few exciting passes (exciting meaning the car didn’t break and went mildly straight).

That was many years ago and a long way away from where the veteran team is now. The dragster was a solid mid 9-second car with a lowest ET of 9 flat.

Lesson 2 – “Spend the money on the good parts, don’t just hope something will work.”

Robinson’s Story

With money in hand from selling the engine and rail, it was time to turn the page and go a different direction. Robinson decided that a diesel-powered funny car was the way to go. It offered a shorter, wider frame; which makes more sense. The weight distribution is a little better and the frame is able to handle the weight better. Dragsters have an issue with cracking frames from the weight and stress of a diesel engine in the chassis. Robinson and team went through that during their first run-in and this time around they wanted to stay away from that issue.

[8]

[8]NHRDA Texas Nationals 2008, Robinson’s first appearance with the new car.

Photos Courtesy of NHRDA, Carl Oberman (www.Texpic.net), John Robinson, and Nigel “Bubba Gump” Gray

Robinson called up a lot of his customers and put the word out he was looking for a new car. It wasn’t long before he dropped 11k into an alcohol funny car chassis and then another 3k on a rearend. The engine he ended up building was a common rail lower-end with a 24-valve head.

This gave him the strength of the common rail block with its girdle, different oil plumbing for oil squirters (the engine is dry-sumped and the oil squirters could be directly fed) and no tappet cover. Yet with a common rail block, he was still able to put a p-pump on and run with a 24-valve head.

Outside of having some front cover issues, the assembly of the engine went together pretty seamlessly. “Probably the biggest challenge of putting the engine in the car was the mid-plate. The front of the engine is tilted downwards to get the transmission’s output parallel to the rearend,” Robinson says. They were never able to get the right angle to directly connect the transmission to the rearend but got around it by using a u-joint on this setup. Behind the transmission a Powerglide connected to a Gear Vendor [9] overdrive was employed to transfer the power back.

(Left) Robinson had so much fuel early on, that it didn't seem to matter how far he advanced the timing; flames were always coming out the stack. (Right) When Robinson added a 24-valve ported and polished head by Dealers Machine, boost, drive and EGT all dropped, indicating the head flowed a tremendous amount more air.

The original transmission was $1,500. After replacing countless transmissions and not making many complete passes down the track, he ended spending over $5,000 in repairs and upgrades, by the time it was done. “Not only were we not making passes which was frustrating, we weren’t keeping up our end of the sponsorship deals because we weren’t making passes,” explained Robinson. “A new turn key ready-built transmission would have been less money in the beginning and that doesn’t even count the thousands of miles we drove to races and we weren’t able to make a pass.”

Lesson 3 – “Buy from people who can help you if you have issues down the road.”

Robinson’s Story

The original torque converter supplier just couldn’t get the converter dialed in: “We would send in a converter that was working ok for a refresh. We would tell them not to touch anything and it would come back 300 rpm tighter,” Robinson said. “Eventually we ended up at Art Carr and their first attempt was almost perfect. It makes all the difference in the world to not only have the right parts, but also the right people helping you,” continued Robinson. Robinson believes that the car really needed a 13-inch converter but no-one made one and the 10-inch converters just weren’t big enough for his set up.

Lesson 4 – “Comic Relief is important to help focus on the task at hand.”

Robinson’s Story

[11]Robinson’s second funny car really helped to bring him to the forefront of diesel drag racing. His team has made multiple passes at various NHRA [12] events. With them having something unique, NHRA fans have been absolutely fascinated by it because they have never seen anything like it before. “First time we ever made a pass at an NHRA race was a great moment. By the time we got back to the pits, we already had two magazines and a TV crew waiting for us,” Robinson chuckled.

[11]Robinson’s second funny car really helped to bring him to the forefront of diesel drag racing. His team has made multiple passes at various NHRA [12] events. With them having something unique, NHRA fans have been absolutely fascinated by it because they have never seen anything like it before. “First time we ever made a pass at an NHRA race was a great moment. By the time we got back to the pits, we already had two magazines and a TV crew waiting for us,” Robinson chuckled.

With all of the attention on the team and the regular stress of going really fast, the team members would get pretty nervous when at the track or under-pressure at the shop. “When we suit up and are on the track, nerves can get pretty high. The best thing we do is to have lots of banter over the radio. We crack jokes and just talk. It helps to keep our mind off the risk and focus on the task at hand,” says Robinson. Even to this day, after hundreds of passes, Robinson and the crew still have to deal with nerves.

Lesson 5 – “Get in bed with quality sponsors and don’t bite the hand that feeds you.”

Robinson’s Story

[13]Robinson and his team had been to race after race, working to get better, working to promote their supporters and making things happen. But beyond that, Robinson has an interesting policy when it comes to sponsorship. “I offer a money-back guarantee,” he says. “If I don’t do what I say, if I don’t get them the exposure promised, then send me an invoice for the parts,” Robinson explains. As far as he is concerned, he has nothing to lose. After learning lesson 3, he would have given the business to that sponsor anyways.

[13]Robinson and his team had been to race after race, working to get better, working to promote their supporters and making things happen. But beyond that, Robinson has an interesting policy when it comes to sponsorship. “I offer a money-back guarantee,” he says. “If I don’t do what I say, if I don’t get them the exposure promised, then send me an invoice for the parts,” Robinson explains. As far as he is concerned, he has nothing to lose. After learning lesson 3, he would have given the business to that sponsor anyways.

“Ultimately, what people don’t realize when they are trying to get sponsors is that it isn’t about what’s in it for me. A good sponsorship helps everyone,” continues Robinson. “And for heaven sakes, let the sponsors know what you’re doing. If the race was a bust, let them know. If it went great, let them know. Good, bad – communication is key.”

Having the attention of a few large sponsors like Power Services [14], Robinson knew that in order to start being competitive, he needed to go faster. Working hard in the off-season, Robinson was able to work out a deal to switch from an automatic to a manual when he built his next funny car.

With a new line of sponsorship deals signed, it was time to build a new car. Robinson went back to the bank and got a 25k loan. He was able to purchase an old John Force car that was built as well as they can be.

[15]This time, they had a solid game plan and the assembly went together much better. “We had to be constantly focused on transferring the weight to the back as we built the car. Ideally we wanted a 60/40 rear-weight bias. The first funny car only managed a 50/50. Turning was very difficult with that much weight on the front tires,” explains Robinson.

[15]This time, they had a solid game plan and the assembly went together much better. “We had to be constantly focused on transferring the weight to the back as we built the car. Ideally we wanted a 60/40 rear-weight bias. The first funny car only managed a 50/50. Turning was very difficult with that much weight on the front tires,” explains Robinson.

With money in hand, Robinson turned to Scheid Diesel [16] to build an engine and for general help with the car. By this time, Dan Scheid had more experience with diesel dragsters than anyone and their rail was the first in the sixes. So, Robinson leaned heavily on his supplier and friend to guild him and help him get where he needed to be.

For an engine, they still used the common rail block but lowered compression, added water injection, custom injectors, 13mm agriculture pump, ported and polished head and a host of other little tricks. Once the combination was up and running, it was Scheid that helped Robinson figure out the clutch and helped him get it dialed in initially.

[17]

[17]Shortly after Robinson left the line, his left rear tire lost traction and he was headed straight towards the wall.

This combination has proven to be extremely reliable, unlike years past. One thing Robinson has always known but it has taken a while for some of the crew to understand and learn, “When something breaks, don’t bad mouth the sponsors.” Robinson has had to let a couple crew members go over the years because bad-mouthing the hand that feeds you won’t get you very far. This new setup was able to get the car into the sevens. It was running consistently 7.80 when unfortunately Robinson kissed the wall. “We didn’t hit that hard, but the cost to replace/fix everything was within a few dollars of buying another car,” explains Robinson. So, we decided to get another car.

With the purchase of the current funny car, the team was able to make a few changes to the rearend and a few other areas. While no one likes crashing, it was a blessing in disguise as the team is now running in the 7.40’s and still has some room left to grow.

Crystal Ball

With the help of Power Services (longtime supporter and friend) and Scheid Diesel, Robinson will be upgrading the power plant to a new billet engine producing 2300+hp. Robinson’s goal is to be the third person in the sixes.

“Diesel Motorsports has opportunities in every direction. Money, sponsors, people are all there. Just do the work, all of it; including the legwork. It isn’t easy, but it’s worth it. There is no reason why we shouldn’t have 10 to 15 tube chassis vehicles at every one of these races.”