Everyone loves a good turbocharger. In fact, it is one of the most common ways that we in the diesel industry make power in our trucks. Well, Ford has now released a statement that the key to their “Best-In-Class Power” on their Power Strokes is due to the shape of their turbocharger exhaust pipe. It’s shaped like a Cobra, no…not a Shelby Cobra, an actual snake. Read all about it in the official company statement below.

Everyone loves a good turbocharger. In fact, it is one of the most common ways that we in the diesel industry make power in our trucks. Well, Ford has now released a statement that the key to their “Best-In-Class Power” on their Power Strokes is due to the shape of their turbocharger exhaust pipe. It’s shaped like a Cobra, no…not a Shelby Cobra, an actual snake. Read all about it in the official company statement below.

Official Company Press Release:

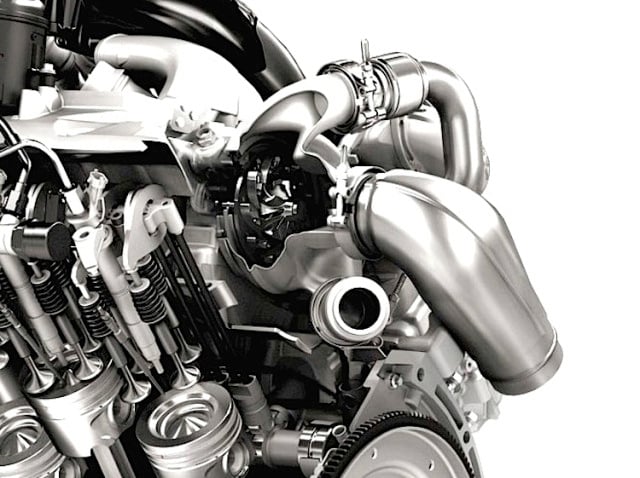

How A Turbocharger Exhaust Pipe Shaped Like A Cobra Head Helps Ford Power Stroke Diesel Make Best-In-Class Power

- Distinctive “cobra head” downpipe helps the 6.7-liter Power Stroke in the 2015 Ford Super Duty achieve best-in-class 440 horsepower and 860 lb.-ft. of torque

- Cobra head shape reduces exhaust gas restrictions to improve engine performanceFord engineers used advanced fluid dynamics computer modeling to create optimal shape and enable maximum output

According to Ford, “The distinctive cobra head turbo exhaust outlet helps the 6.7-liter Power Stroke V8 diesel in the 2015 Ford Super Duty achieve best-in-class 440 horsepower and 860 lb.-ft. of torque. The cobra head shape reduces exhaust gas restrictions to improve engine performance.”

While some might hold their breath seeing the fearsome shape of a king cobra, Ford engineers discovered that designing the turbo exhaust outlet, or downpipe, of the 6.7-liter Power Stroke V8 diesel like a cobra head helps the engine breathe easier.

Ford’s second-generation 6.7-liter Power Stroke® V8 turbo diesel now boasts 440 horsepower, up from 400 horsepower, and 860 lb.-ft. of torque, up from 800 lb.-ft, across all Super Duty models from F-250 to F-450.

Ford is the only heavy-duty pickup truck manufacturer that designs and builds its own diesel engine and transmission combination, ensuring the powertrain will work seamlessly with all chassis components and vehicle calibrations – from concept to execution. This approach also enables Ford engineers to optimize the vehicle’s performance across the entire lineup.

A key Ford innovation on the original 6.7-liter Power Stroke V8 turbo diesel was its so-called reverse-flow layout. The advanced design places the exhaust inside the engine’s V-shape while the air intake is positioned on the outside of the V. This segment-exclusive design naturally improves a variety of attributes:

- Shorter airflow from the exhaust system to the turbocharger sitting between the engine’s cylinder banks improves turbo responsiveness – key to providing torque quickly to truck customers when they need it most

- Positioning the turbo inside the engine’s valley helps the engine efficiently use the hot temperatures, improving performance and efficiency, while also reducing noise, vibration and harshness

The hot-V design of the 6.7-liter Power Stroke – with its turbocharger bolted directly onto the compacted graphite iron engine block within the V of the V8 – provides exceptional packaging, structural advantages, and improved noise, vibration and harshness characteristics.

Getting the hot exhaust gases from the turbocharger out of the engine V with minimal obstruction to exhaust flow, which aids in generating power, is the job of the cobra head.

Here’s how it works.

Any sharp turn or kink in an exhaust system can disrupt the flow and increase the pumping work an engine must do, reducing efficiency. The Cobra head acts like a widened, banked turn, allowing exhaust gases to flow smoothly through the 90-degree turn from the engine to the aftertreatment system and reduce backpressure. By reducing pumping losses, the design improves efficiency and allows greater torque production.

Any sharp turn or kink in an exhaust system can disrupt the flow and increase the pumping work an engine must do, reducing efficiency. The Cobra head acts like a widened, banked turn, allowing exhaust gases to flow smoothly through the 90-degree turn from the engine to the aftertreatment system and reduce backpressure. By reducing pumping losses, the design improves efficiency and allows greater torque production.

By applying hundreds of hours of advanced fluid dynamics computer modeling simulations to the design, Ford engineers were able to optimize the shape of the pipe bend.

“Fluid dynamics allowed us to precisely tune the curvature and width of the pipe to optimize exhaust gas flow,” said Robert Wade, engine air path technical leader. “It turns out that a downpipe shaped like a cobra head is the ideal design for air flow and breathability, which we validated through thousands of miles of durability testing.”