When you survey the current landscape of high-performance vehicle options it becomes obvious there are a plethora of choices available. Taking that a step further, the aftermarket offerings for these vehicles is deep, with plenty of ways to add horsepower. Bolting on horsepower is great, but you need to make sure you have the harmonic balancer to match the power you’re adding to an engine or there could be serious consequences.

A harmonic balancer could easily be considered one of the most important parts of an engine that doesn’t get the attention or respect it deserves. The harmonic balancer itself looks simple, however, it functions in a complex environment filled with parts that move at a high rate of speed under extreme conditions.

When a manufacturer releases a vehicle, the stock harmonic balancer is only designed to work with a certain level of horsepower, torque, and RPM. These units are typically made with a cast ductile iron center hub, outer inertia ring, and bonded layer of elastomer material holding everything together. If you change how much horsepower an engine produces, it will begin to overwork that stock harmonic balancer in a hurry.

An OEM harmonic balancer was never designed to see elevated levels of horsepower. When you mix that with normal wear and tear you have a recipe for premature failure.

Nick Orefice and Brian LeBarron from Fluidampr help customers ensure their harmonic balancers are up to the task of dealing with high levels of horsepower. They explain why an OEM damper needs to be inspected or replaced as you increase horsepower.

“The OE damper is tuned to a specific frequency set by the manufacturer; this is a narrow band targeted at the most harmful vibrations. It is very important to inspect it regularly for separation, dry rot, and slippage. Sometimes it can be very difficult to tell or see the actual wear, in which case we would recommend replacing if there’s a lot of miles on the unit, or it’s getting up there in age. This is especially true if the engine is modified,” Orefice says.

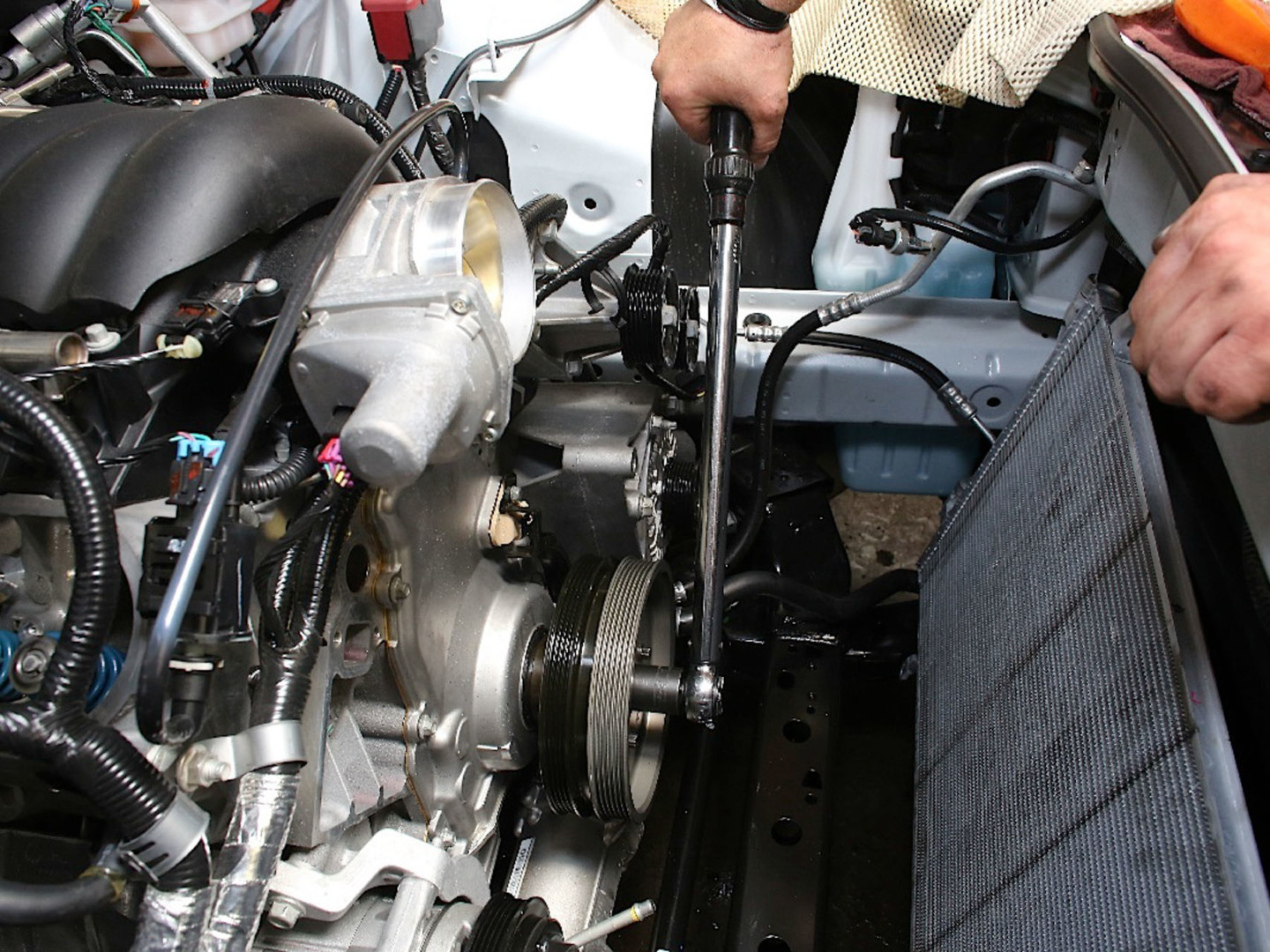

Adding an upgraded harmonic balancer is a great way to keep your engine from having serious issues as horsepower increases.

LeBarron goes a little deeper into the issues a stock harmonic balancer will experience as you up the power.

“Excessive horsepower and torque that overwork the balancer for what it’s designed for, along with exposure to oil, solvents, and age can cause the deterioration of the elastomer and/or cause the hub to fracture. When the stock balancer fails and separates, it can cause untold damage inside the engine bay and pose a safety hazard at the race track. Most racing sanctioning bodies require an SFI 18.1 spec harmonic damper for safety; SFI 18.1 sets the standard for harmonic damper construction and rotational integrity.”

The stock elastomer harmonic balancer has its limits and can only do so much. – Brian LeBarron.

A harmonic balancer is designed to keep crankshaft torsional vibrations in check that occur when the engine is running. So, it doesn’t matter what kind of change you make to the engine, adding more horsepower will change its harmonics. These new harmonics will have an impact on the bearings, rotating assembly, and even the crankshaft itself.

According to LeBarron, there are two main problems that will occur when you change an engine’s horsepower output without upgrading your harmonic balancer.

“First, modifications to the rotating assembly will shift where the worst harmonics occur. When the weight and material composition of the pistons, connecting rods, flywheel/flexplate, or crankshaft changes, it will create new engine harmonic properties. Now, the stock balancer is tuned to a very narrow frequency range under stock conditions. It will become ‘out-of-tune’ to do its best job when engine mods are made. Second, performance parts that increase torque will also increase vibration amplitude. As the stock balancer works harder to keep amplitude in check, the heat build-up doing so will cause the elastomer to crack, bulge, and fall apart.”

As an engine sees an increase in torque and RPM it will change the torsional vibration characteristics — this is why having a harmonic balancer that matches your increased levels of horsepower is important. That increased level of vibration is tied directly to how much your crankshaft is twisting and rebounding.

“RPM plays a role in determining torsional vibration frequency. Frequency is measured in hertz, or cycles per second. The higher the RPM, the faster the cylinders are firing, and that generates more vibration cycles in that time frame. RPM is also critical because at some point you may cross the natural resonance frequency of the rotating assembly. The resonance frequency is the point when an object will vibrate on its own. If torsional vibration crosses resonance frequency, then amplitude spikes. This is most likely when you will see sudden crankshaft failure. If you exceed stock RPM limits, you may inadvertently find a resonance point,” LeBarron explains.

Rigorous testing is part of the process when you’re trying to “tune” a harmonic balancer. Before a company like Fluidampr can create a balancer, it needs to understand what kinds of vibrations an engine will produce at different levels of horsepower. As engine torque and RPM go up, the harmonic balancer must be ready to fight the potentially damaging vibrations being created.

“Getting a baseline of the engine is a very important part of any damper design. As technology advances we see manufacturers turning more RPMs to get the most out of an engine so they can locate the sweet spot where the optimal power is achieved. We use our testing equipment to find the natural resonance and harmful torsional vibrations. That information is fed into our computer model to get our target and construct a damper for optimal performance,” Orefice explains.

Getting a baseline of the engine is a very important part of any damper design. – Nick Orefice

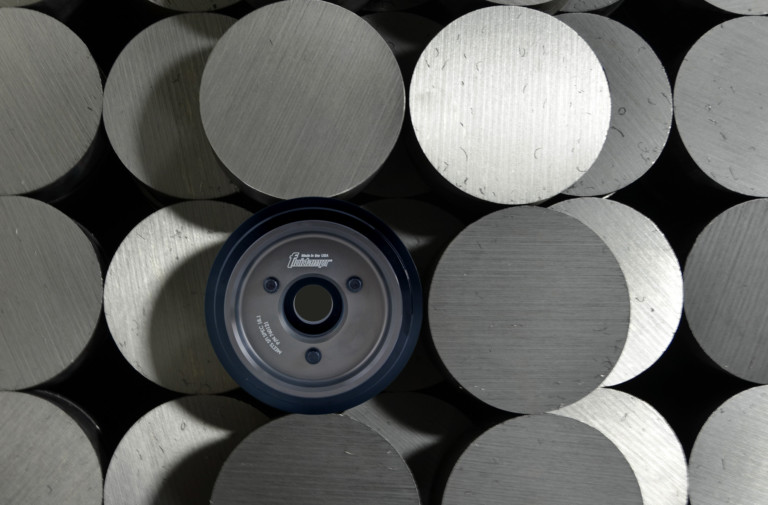

Fluidampr has worked hard at making sure its viscous-style harmonic balancers can perform in the most extreme conditions. Since these dampers don’t need to be rebuilt or retuned, it makes them a great choice for those who have a modern muscle car that’s making a lot of horsepower.

Upgrading your harmonic balancer to match your engine’s power output is just part of the equation. A more robust balancer is a rule requirement for safety reasons and that’s something Fluidampr takes seriously.

“Fluidampr performance dampers are rated SFI 18.1 spec for structural integrity. Beyond the safety standard required for most race sanction bodies, the outer housing is a robust, laser-welded design that holds up to high torque and horsepower stress. Inside a Fluidampr is an un-bonded inertia ring that shears through a thin layer of high-quality viscous silicone, so no tuning or maintenance is required. These quality design features provide for a superior lifespan and optimum vibration control across the RPM range,” LeBarron says.

So as you can see, making sure your harmonic balancer matches the power output of your engine is pretty important. The right harmonic balancer will not only help your engine last longer, but it will also make sure it performs at the highest level possible so you can use every ounce of horsepower.