Very few business owners can say they helped design an engine at the OE level and then went on to push that same powerplant to the brink in the aftermarket. Come to think of it, we can only name one: Jerry Lagod of Hypermax Engineering.

While working for International Harvester, he had a hand in the venerable DT466 inline-six engine’s design and development, and would later be paid to squeeze more than 500 horsepower out of them. But after International drew the line on how far they were willing to take their factory-backed tractor pulling program, Lagod opted to go into business for himself and take the engines he knew, inside and out, to the next level.

Opening up shop in an old dairy barn, Lagod started out with little more than a used injection flow bench and a head full of ideas. But once customer John Thompson began to dominate the Super Stock tractor class with his IH 1466, word spread fast that Lagod was the man to see.

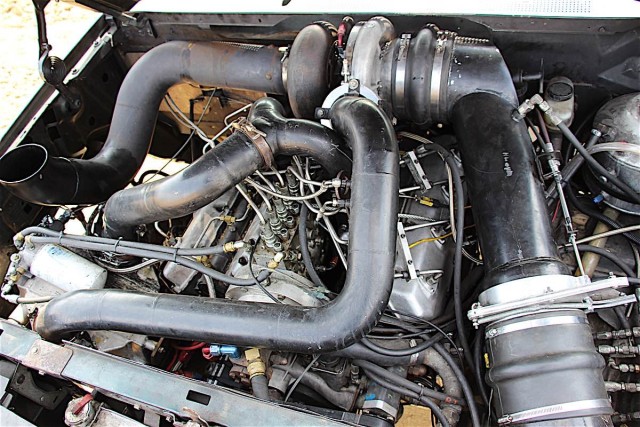

The most successful example of Hypermax’s P-pumped 7.3L engine package is on full display each summer in this ’97 Ford F-350, which is named Relentless and is operated by Joe Wiltse and Rob Thurow. The truck primarily competes in the Illini State Pullers organization, and it finished Second in the 7,800 Pound Pro Stock Diesel Truck points chase in 2015. Take it from us, in a class where the B series Cummins can be found under the hood in nine out of 10 trucks, this machine is definitely a breath of fresh air. Photo courtesy of JPPullingProductions.com

Soon after that, Hypermax would pioneer larger turbochargers, water injection, and side shields to conceal what was being done to reap so much power out of the IH mills. Essentially, Lagod made red tractors the only viable platform to win with for decades.

Now, more than 40 years later, Lagod and the Hypermax brand are still a household name in tractor pulling. The company manufactures its own engine blocks, cylinder heads, turbochargers, injection pumps, connecting rods, intake manifolds, and various other competition-only parts.

Even though big horsepower improvements are getting harder to come by in the upper echelon of tractor pulling, Lagod is always working to find ways to keep his customers at the top. We recently caught up with Lagod for an interview. Read on for the backstory behind his helping create the DT466, how he added power to them at IH headquarters, and see what his company is currently up to.

Many of you know or at least suspect that a close tie exists between Hypermax and International. We’re here to tell you that your suspicion is completely warranted and true—but it goes even deeper than that. Did you know the first fitment of a 6.9L IDI V-8 into a Ford truck was actually performed at the Hypermax facility? Armed with this knowledge, it’s even easier to see why Hypermax basically had an aftermarket turbocharger system available the day the first diesel-powered Fords graced dealership lots.

Digging Deeper

Diesel Army: Did you help design and develop the 466 ci International inline-six, better known as the DT466?

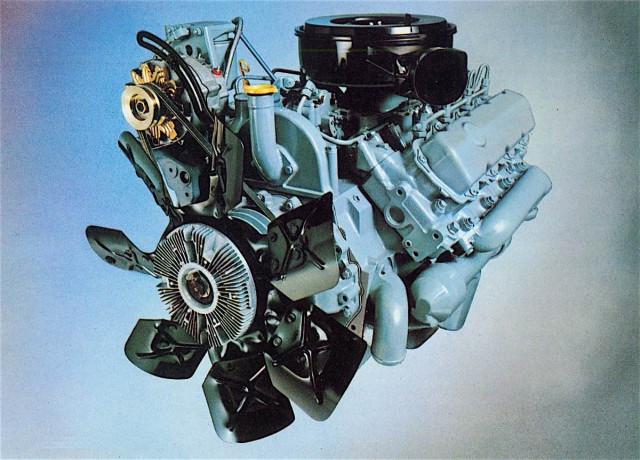

Jerry Lagod: Yes. International started working on what became known as the 300/400 series engines (312ci, 360ci, 414ci, 436ci, and 466ci), and I was on the design and development team. The 414 and 436 were designed for agricultural applications, while the 466 was designed for light bulldozers and construction equipment. The 400 series engines were intended to replace the aging 407ci engine.

The DT466 utilizes a wet sleeve block, which is unique for a medium duty engine, and allows rebuilds to be performed in-frame (or in-chassis). Made from cast-iron, the block itself features a deep saddle casting, where the crankshaft is housed 100 percent within the block. The main caps are secured with a girdle. Forged-steel connecting rods also add to the engine’s burliness, not to mention their ability to handle upward of 1,200 hp.

DA: We’ve been told that the older 407ci engines ran better (in tractor pull competition) than the newly released 414s and 436ci engines in the late 1960s, and that International gave you the task of making the 414 and 436 better performers. Is this true?

JL: It is true. The newer engines were losing to the older engines at tractor pulls and dealers (customers of International) were complaining. So, knowing that I was a car racer and drag racer, International plucked me out of the production group and said “you’ve got to make this new engine beat the old one.”

Of all the tractors Hypermax has helped propel into the winner’s circle over the years, Esdon Lehn might have the most name recognition. Known as the King of Smoke, Lehn has piloted his Super Stock tractor (an IH 1486 called “Red Line Fever”) to an incredible 12 Grand National championships in the National Tractor Pullers Association (NTPA). Other successful Hypermax customers would be John Thompson in the “Bad Dog” machine, Danny Dean campaigning the “Rooster,” and John Klug, who drove an IH 1066 known as “Red Baron.”

DA: What types of modifications did you make in order to get these engines to compete with the older, hotter running 407ci mill, and how much horsepower were you able to get out of the 414 and 436?

JL: 500 to 600 horsepower with one turbocharger. I remember that International was being fined for smoke violations though, so we had to do dyno testing at night. Being that the rotary pump (on the 414, 436, and 466) was shy on fuel, we made bigger plungers for it—but we did not do an inline pump at this time. And even though I created an inline pump system for them while at International, we were never allowed to implement it due to legal reasons. We were able to get enough power out of the rotary pump that they were satisfied.

DA: So you came up with an inline pump system for the DT466 while still working as a Development Engineer at International? Is that what sparked your need to go into business for yourself and take things to the next level?

JL: Yes. International actually wanted me to start my own company to support the inline pump customers. They even loaned me the inline pump package that I designed.

It might not be bolted to a red machine, but a giant Hypermax turbocharger helps keep this particular 6030 model John Deere at the front of the Pro Stock Class. The 5.2-inch inducer charger produces more than 100 psi of boost and allows the engine to make in the neighborhood of 3,000 hp. This illustrates Hypermax’s primary source of business: offering exotic parts that allow the nation’s top-running tractors to both make and survive huge horsepower.

DA: We assume you were able to push a lot of the factory DT466 engine components pretty far, horsepower-wise. Could you share with us what kind of power these engines are capable of before you begin to find weak links?

JL: Out of the box, a 436 or 466 would make an easy 1,200 hp without doing anything—just put the fuel and air to it and it would live. The first weak link we came to was the head gasket, so I designed a wire ring gasket, which evolved into the dynamic gasket we’ve used for the last 25 years. We didn’t need to get into making billet connecting rods and crankshafts until 15 years ago.

In recent years, Hypermax has sponsored a truck with a 7.3L Power Stroke-based V-8 engine and the company’s inline pump (P-pump) package. Published as being capable of making more than 1,800 hp with a single turbo, this type of engine is extremely unique in a sport where inline-six Cummins mills typically rule the day.

DA: We know Hypermax is a household name in the tractor pulling world, but what is a typical Hypermax customer looking for when they contact you?

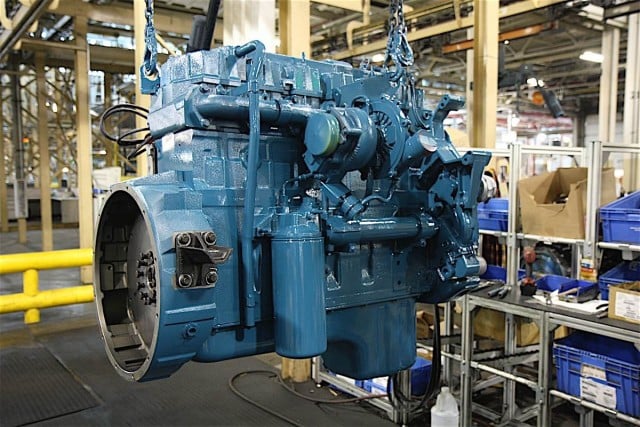

JL: Our main business is not road vehicles; it’s engine blocks and heads. We’re in the component business. We manufacture our own turbochargers, injection pumps, intake manifolds, and offer piston and sleeve kits. We might assemble two to four engines a year, so most customers buy the components to build the engine themselves or have another company do it.

Thanks to implementing water injection systems onto tractors; utilizing inline injection pumps and staged turbocharging to get his customers as much horsepower as possible; and introducing the concept of using side shields, we have no problem referring to Jerry Lagod as the unofficial Godfather of modern tractor pulling. However, he’s also [unofficially] the Godfather of what is arguably the greatest diesel engine ever assembled: the 466 cubic-inch inline-six from International. It’s truly extraordinary that the same person who helped design this legendary engine also went on to push it to its very limits in the aftermarket.