The 6.4-liter Power Stroke is a love it- or hate it- kind of engine. After a short production run and strong opinions in both camps, you may wonder if they are worth the gamble. With more 6.4-liter trucks hitting 10 years old, there are plenty to choose from in used inventory and deals popping up every day. We set out to see if those deals are really worth taking a chance on.

Our first glance at the 2009 Ford.

The truck we found is a white 2009 Ford F-450 dually with roughly 113,000 miles. The crew cab offers plenty of space and the black Lariat interior is surprisingly clean with little signs of wear. With the added bonus of four-wheel drive, this could be the perfect base for a new tow rig. At less than $10,000, the truck initially seems like a steal.

However, the price tag reflects the reality that the truck is running rough and accompanied by a distinct tick. Is it a quick fix that could make a good investment? Possibly. Diesel Army dives in to take a look at what the knock could mean.

First Look:

We know that it is not uncommon for 6.4-liter Power Strokes’ to have rocker arm issues after 100,000 miles, but there is always the chance that it is a more serious problem. To start, we pull the oil fill cap to check engine blow-by and find no puffing at idle. While limited, this quick test leaves us feeling confident the pistons are sealing relatively well in the cylinders.

This simple test can give you an idea if the truck has excessive blow-by.

Next, we listen to see if the noise is louder on top of the engine or under the truck. After further inspection, the ticking is louder on top. This is a good sign as a hydro-locking cylinder or a spun main or rod bearing are generally heard lower in the engine.

Listening to the truck can give you clues about what is causing the noise.

With the truck still at idle, we follow the exhaust. We are listening to see if the noise grows more noticeable, signaling an intake valve not opening properly. The factory exhaust makes it hard to hear anything, so we move back up front looking for more clues.

Pulling the intake is quick, but provides valuable insight.

Digging Deeper

After further inspection, the knock was substantially louder with the intake off. Hoping for a quick fix, we decided to roll the dice. With the truck at our home shop, we continue our investigation. We know that with the intake removed the ticking immediately sounded more like thumping. This could mean that an exhaust valve is not fully opening.

The truck seems like a good deal, but finding out what is going on inside this engine will determine just how good.

When the valve does not open, the exhaust gasses are trapped after the combustion event. On the next intake stroke, the remaining heat and flame escape allowing only a small amount of fresh air in. As this continues, the rapid escape of exhaust through the intake causing a noticeable thump.

To narrow our search down, we start with a scan tool to check relative cranking compression. For this test, the computer goes off RPM to sense which cylinder is lower on compression. The engine speeds up faster when it hits a cylinder with an issue because it is not squeezing the air as hard. We run the test multiple times and narrowed it down to two cylinders on the same side.

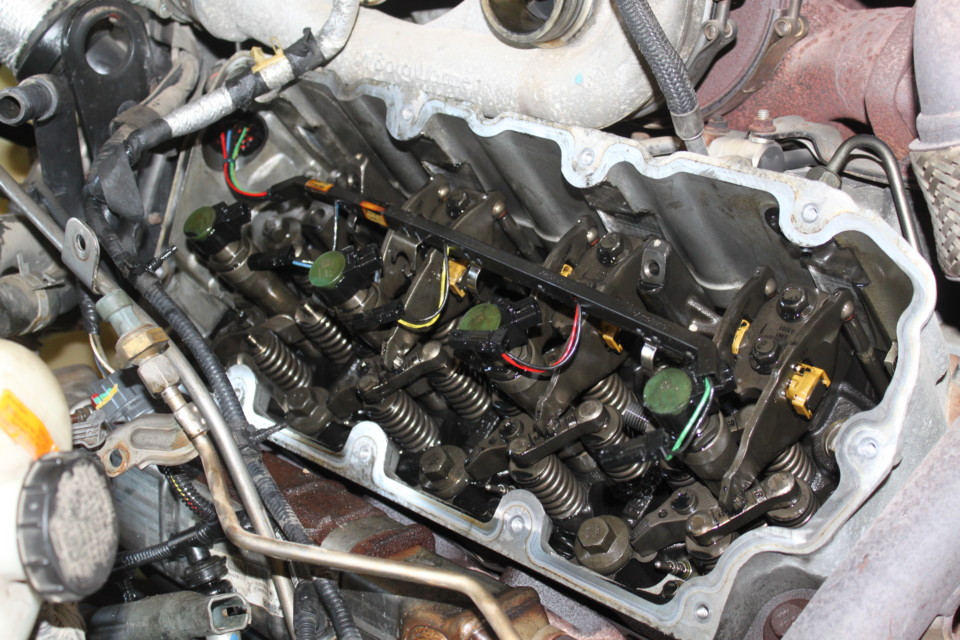

Now that we’ve narrowed down the area of the problem, we pulled the valve cover and immediately see the problem. A rocker arm bridge is laying on the head, one of the rocker arms was bent, and one of the pushrods was bent. After replacing the rocker and bent pushrod, everything was put back together and the engine was started. Unfortunately, the engine still has a thumping at RPM but idles fine.

Disappointed that the quick fix did not solve the problem, we run the relative cranking compression test again. The same cylinders are identified so we remove the valve cover again. Nothing is visibly out of place, but the rocker arm has .0050 – .0075 of travel. The hydraulic lifters in Power Strokes should not create this much travel, telling us there is more to the story. We check the valve heights and confirm they are consistent with the rest of the engine, pointing to a probable lifter failure.

The cylinders in question are upfront with limited viewing access. Using a borescope, we try to verify the issue. The view is limited, but we can see that light is not reflecting off all of the lobes consistently meaning the cam is damaged. We likely have at least one lifter failure.

Knowing that there is internal damage, it is time to make some decisions. What is the best course of action to keep the truck a good deal? We have some room to work given the purchase price and current trade-in value around $20,000. At a minimum, we need to replace any damaged lifters and the camshaft. A better scenario is to go with a fresh set of lifters all the way around and make any internal upgrades now to support our future plans for the truck.

It is time for us to reassess our plans for the truck and gather parts. Stay tuned for Part 2 where we will open this 6.4-liter Power Stroke up to share the damage and walk you through our lifter and camshaft install. Have you taken a gamble on a truck? Let us know how it turned out in the comments below.