That’s right, we found more parts to improve the reliability of the 6.0-liter Power Stroke. While many have given up on these problematic models, others haven’t. When this engine has the proper upgrades, it runs very well. If the right parts are used, these trucks are a solid platform. Improving the Power Stroke cooling throughout this engine will help increase the odds of keeping it running, rather than up for sale.

That’s right, we found more parts to improve the reliability of the 6.0-liter Power Stroke. While many have given up on these problematic models, others haven’t. When this engine has the proper upgrades, it runs very well. If the right parts are used, these trucks are a solid platform. Improving the Power Stroke cooling throughout this engine will help increase the odds of keeping it running, rather than up for sale.

The crew at Strictly Diesel saw a limitation in the cylinder head design and came up with a kit to solve it. At that point, the Driven Diesel 6.0L Coolant Return Kit was born. In factory form, the cylinder heads rely on coolant jackets for circulation. When the coolant reaches the rear of each cylinder head it only has one path to take. This can hinder cooling.

The limited flow through the heads creates hot spots. This engine is notorious for head gasket failures but also for cracking around the injector sleeves. When cracking occurs, it will allow fuel contamination in the cooling system. The longer superheated coolant sits in the water jackets the more prone they become to cracking.

Power Stroke Cooling: The Solution

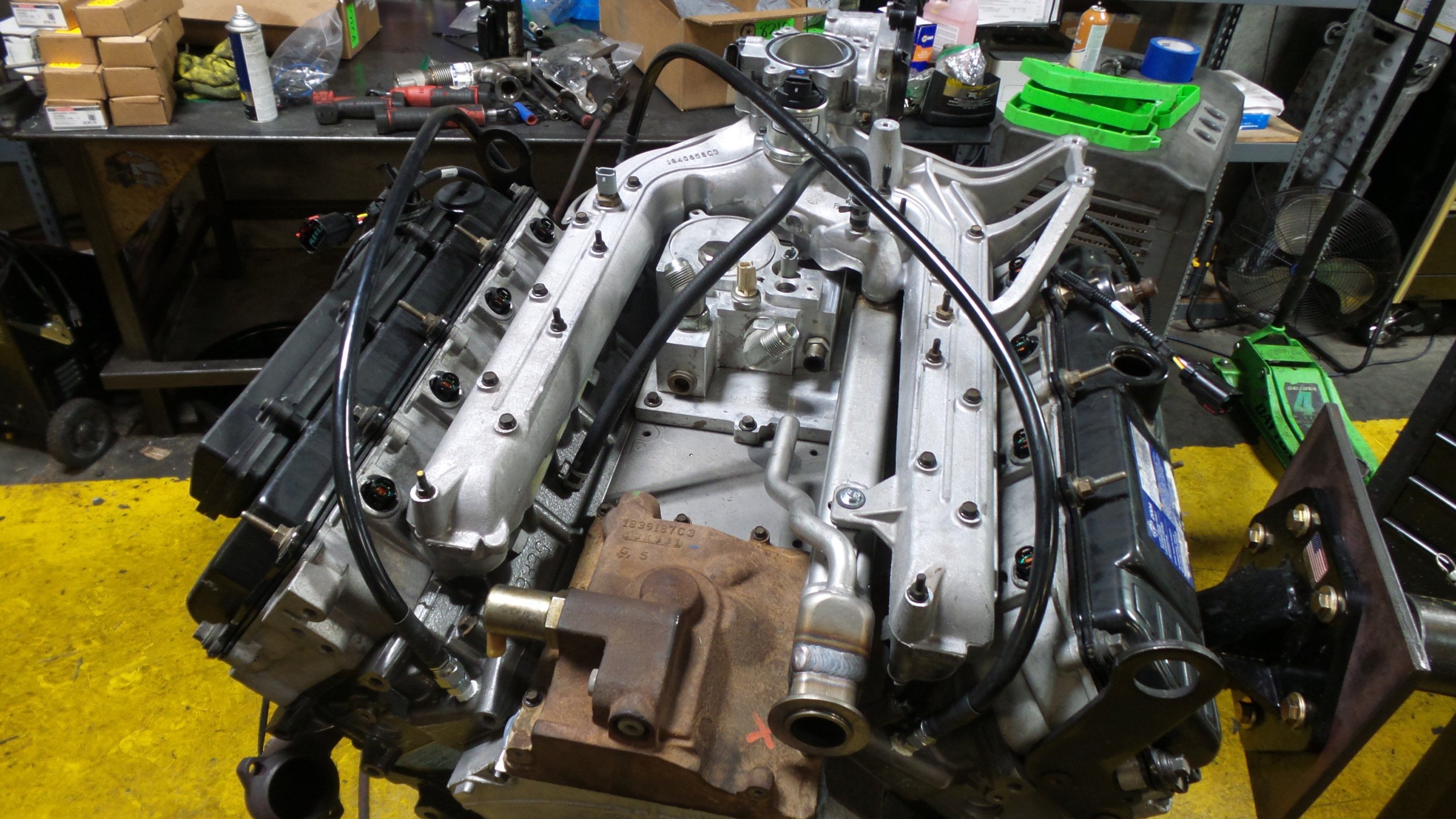

To eliminate this issue, this Power Stroke cooling return kit adds a hose at the rear of each cylinder head. It then flows into the thermostat housing. The design improves the coolant flow and helps it get back to the radiator for cooling. The hoses were designed to last and are constructed of high-quality, braided, stainless steel over Teflon. The outer layer is a black protective coating. Also included in the kit are the four fittings which secure the hoses to the heads and thermostat housing.

Coolant return lines installed.

Time To Get Dirty

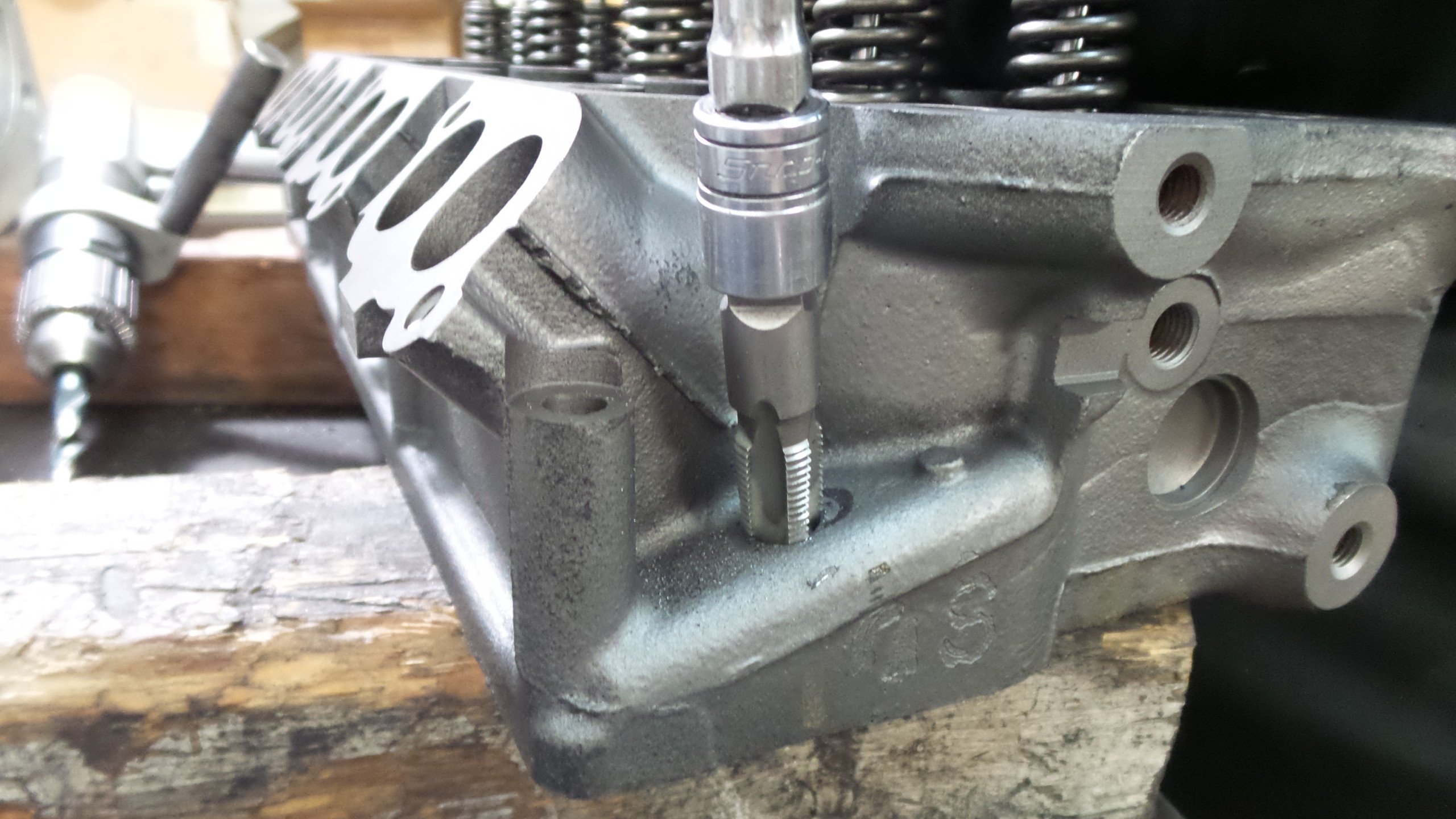

Installation of the Power Stroke cooling return kit can only be performed when the cylinder heads are removed from the engine. If you’re not confident using a thread tap then they suggest using a qualified mechanic to perform the installation. Since this may be unnerving to some, we asked Nate Brekken, co-owner of Strictly Diesel if he had any installation tips.

Nate had this to say. “If you have or will be installing an aftermarket fuel system, then you’ll want to install the rear fuel lines first. This will ensure the coolant return fittings have enough clearance and do not interfere with any fuel lines. To prevent damage and make life easier, be sure to use a new or sharp drill bit and thread tap. Also, use a lot of lubrication when using the tap.”

Installation of the pipe thread fittings.

Instructions are supplied for a reason, so be sure to read them before installation. As with all of Driven Diesel’s products, their install guide is very detailed and includes full-color illustrations. If you follow them closely, you’ll end up with a job well done! Now it’s time to get the engine back in the truck and fill it with fluids. Hopefully, your cooling system woes are behind you so you can bleed Ford blue instead of coolant.

For more information about Strictly Diesel, head over to their website here. For more industry news and updates, stay tuned to Diesel Army.