Spotting fresh oil in the valley of an OBS Ford often leads to a quick gasket swap, but this project escalated immediately into a CNC Stage 2 HPOP install after uncovering a catastrophic pump failure. What started as chasing a messy leak and long crank times exposed stripped threads on the original housing, proving that the factory hardware had finally given up the ghost.

Tearing Down The Valley

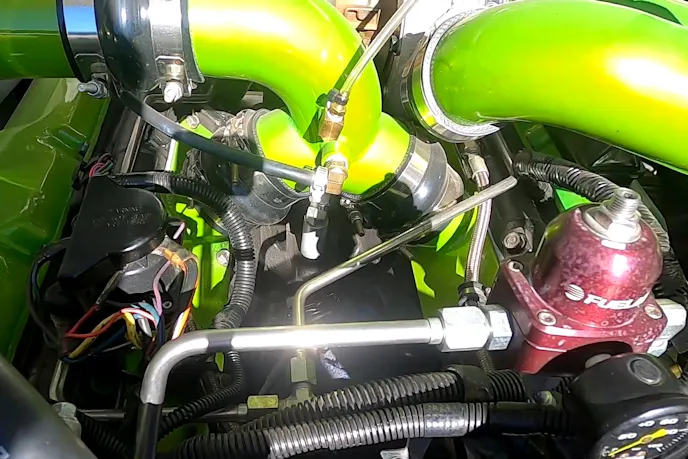

Pulling the old pump revealed the grim reality of stripped threads and leaking fittings that no simple O-ring swap could fix. Since the pump had to come out, it made sense to tackle the lines and add a high-pressure crossover (HPX) line. While an HPX line won’t magically add horsepower, it connects the oil rails to balance pressure between the heads. This simple addition helps smooth out the idle and quiets down that infamous “cackle” from the split-shot injectors, or at least as much as you can quiet down a loud 7.3-liter diesel.

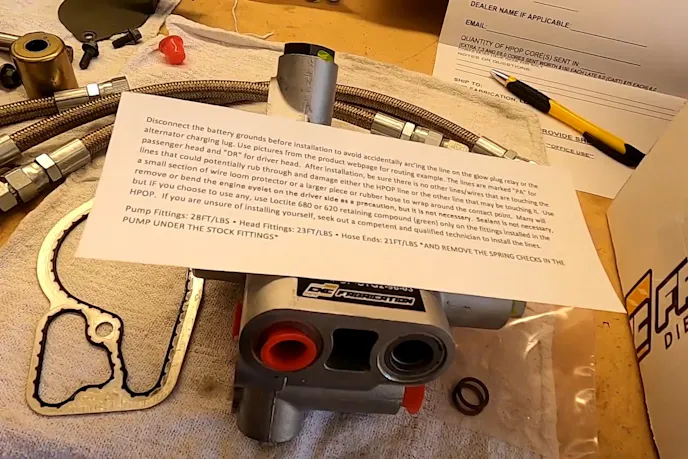

Bolting Down The CNC Stage 2 HPOP

The installation process for the new pump required paying close attention to the details, especially torque specs. The pump fittings need exactly 28 lb-ft, while the head fittings take 23 lb-ft. A small hiccup occurred with the mounting gasket, as the kit included a late-model style incompatible with the early block, but reusing the original gasket solved the fitment issue. Reinstalling the IPR valve usually demands a pricey specialty socket, but drilling out a standard 1-1/8-inch socket to fit over the solenoid saved cash and worked perfectly to hit the required 35 lb-ft.

Firing It Up And Hitting the Road

After priming the reservoir with a quart of oil, the first crank revealed a loose fitting that sprayed oil everywhere, proving that even experienced wrenchers miss a spot occasionally. Once tightened and cleaned, the truck roared to life. The test drive showed an immediate difference. The old sluggishness above 2,000 rpm vanished, replaced by a strong, linear pull all the way to 3,500 rpm. The engine held 38 psi of boost smoothly, and the smoke output dropped significantly, clearing up almost instantly when the turbo lit.

The Verdict On The Upgrade

This CNC Stage 2 HPOP project by My Garage proves that throwing parts at a truck isn’t always about chasing big dyno numbers, but about restoring reliability and driveability. The new pump eliminates the tired, restrictive check valves of the stock unit and keeps the injectors fed with enough oil volume to support hot tunes. For the price point, it beats out stock replacements without hitting the wallet as hard as the extreme high-end pumps.

You might also like

Fireballs And Midnight Rebuilds: Diesels Survive No Mercy 16

Several diesel teams faced a grueling week of mechanical failures and midnight engine rebuilds at No Mercy 16.