We love big power and with a diesel it only takes two things to make that big power; air and fuel. As we start adding more air and fuel to our truck, they become less and less friendly for street driving. With the right tuner, a lot of fuel can be pulled back which helps control exhaust gas temperatures (EGT) and smoke. This makes street driving a little more manageable, but air is a different situation.

The main supplier of air is a turbocharger with few exceptions on today’s modern diesel engines. When upgrading a turbocharger, there are pros and cons that must be weighed and balanced. Sure, you can size your turbocharger to give you all of the top end air flow you need to make that HUGE power, but it probably won’t make any power down low and it won’t be very streetable. Or course, you can go the other way and put on a small turbocharger that gives you insane throttle response, but chocks out after a few hundred RPMs. For the vast majority of us, we try and balance our power needs against our driveability needs.

Well, recently BD Diesel Performance has come out with a device, called a Turbine Diverter Valve that can be used in conjunction with most turbochargers to aid in initial spool up. To really understand how the Turbine Diverter Valve helps spool up, we need to look at the major components of a turbocharger and what some of the tradeoffs are.

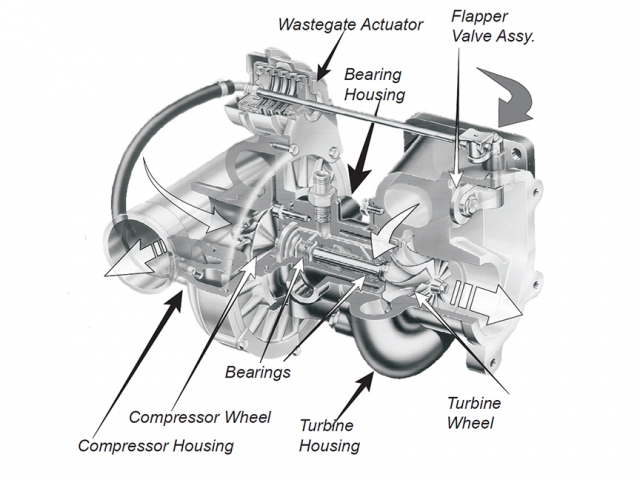

Parts of a Turbocharger

Turbochargers have a few major parts. Here’s the five major components for your quick review:

- Compressor wheel: On the fresh air-side, the major working part is the compressor wheel. These come in a wide range of sizes and design. Generally, larger wheels weigh more (the exceptions would be when different materials are involved: titanium, cast aluminum, billet aluminum etc.). These wheels require energy from the turbine wheel in order to spin and move fresh air.

- Compressor cover/housing: For the most part, there is usually a single size compressor cover designed for a given range or size of compressor wheels. There are exceptions, where frame sizes start overlapping (basically, the smaller size turbo has larger compressor wheels that are in the range of a larger size turbo with smaller compressor wheels).

- Bearing housing: This area houses the bearings that support the shaft. While this area doesn’t directly add power, the design and style of the bearings do alter the durability and initial spool up of the turbocharger (that’s another article).

- Turbine wheel: The turbine wheel is one of the most critical aspects to a turbocharger. The size, design and weight of the wheel plays a huge role in how much exhaust it can move and what type of energy it is able to produce. Bigger isn’t always better.

- Turbine housing: The turbine housing is what directs the exhaust from the manifold to the turbine wheel. As the exhaust flows through the volute (passage in the turbine housing), the volute shrinks. This reduction in area, directs the exhaust into the turbine wheel.

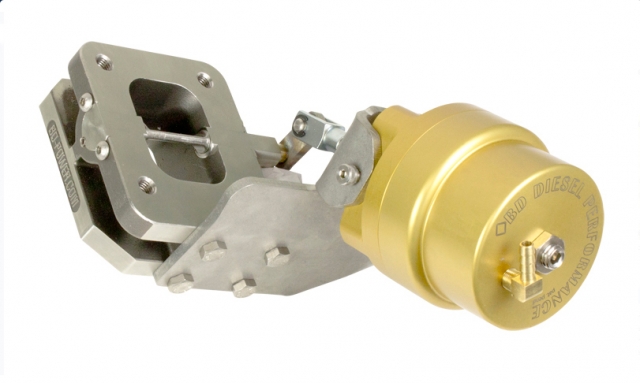

BD Diesel’s 6.0 Power Stroke turbocharger upgrade with their Turbine Diverter Valve. Thanks to the Turbine Diverter Valve, these chargers spool up much quicker which vastly improves drivability.

Changing any of the five major components listed above will change the performance of the turbocharger. Certainly, the aerodynamic package (the compressor and turbine wheels) will have greater effects than a bearing package, but they all will change the characteristics of the turbocharger. Let’s keep it simple and assume the bearing housing and bearings are the same for all of the turbochargers discussed in this article. In addition, let’s assume that the compressor cover size is the same for all compressor wheel sizes within a given frame size.

So, as the turbocharger is upgraded to handle more horsepower it will generally take more time to start creating boost (called lag). If it is a small upgrade, this lag may only be a couple hundred RPMs, where a slight difference in driving or tuning can make up the difference. As we seek more and more horsepower, there is a point where driving style and tuning cannot make up the difference.

The biggest cause of this is a combination of compressor wheel and turbine housing size. On the exhaust side, the turbine housing size plays a huge role in how the turbocharger performs. The larger the housing (within reason) the later in the RPM the turbocharger will start to create boost but the more horsepower that it can support at higher RPM. The smaller the housing, the earlier the turbocharger will start creating boost but at a cost of more restriction at higher RPMs (costing you horsepower).

On the compressor side of the equation, the issues are weight and blade design. While the blade design affects how quickly the boost is created and how much boost can be supported, this really isn’t something most people can change and we will assume all compressor wheels are the same for this article. So, the increased diameter means more weight. That weight means it takes more energy being produced by the turbine wheel to create boost pressure. This takes us back to the earlier discussion of sizing the turbine housings. Larger wheels need more energy and that energy can be had with smaller housing, but at a cost of top end power.

So, What Is The Solution?

Well, that is where BD Diesel Performance’s Turbine Diverter Valve comes into play. The engineers at BD Diesel Performance have designed a part (the Turbine Diverter Valve) that aids in the spool up and performance of a turbocharger. This increased performance is the result of keeping the energy level up at low RPMs and reducing the choking (restriction) caused by a small turbine housing.

Turbine housings are sized by their A/R. This is the ratio of volute inlet area divided by the radius (measured from the centroid of the volute to the center of the turbine wheel). In a given frame size, take the BorgWarner S400 for example, there are multiple A/R’s available. For the S400, the most common housings available are 0.90, 1.00, 1.10, and 1.25. As a general statement, the radius’ are all about the same size for these housings. So, it is the increase in volute area that is the major difference between these sizes. As the area increases, it causes the exhaust to expand and cool (resulting in less drive pressure) and reduces EGT’s (Exhaust Gas Temperature).

All of these housings are divided (meaning there are two volutes that makeup the total area), and each volute is approximately half of that (i.e. 0.45, 0.50, 0.55, 0.625).

We can put on a bigger A/R ratio… And we can spool the turbo. The big benefit of that is that at the top RPM the larger turbine housings will develop more power- Brian Roth

Here is where the genius in the design of BD Turbine Diverter Valve lies; the engineers realized that if they could simply send 100 percent of the exhaust into one side of the volute, the housing would perform like a much smaller housing. It isn’t “apples to apples” (meaning a 0.90 A/R will not act exactly like a 0.45 A/R), but there is a substantial increase in response. This reduced volute size keeps the exhaust energy up at low RPMs, allowing more energy to be transferred into the turbine wheel.

As the volume of exhaust gas increases to a point that the reduced area isn’t needed as much, the Turbine Diverter Valve starts to send exhaust to the second passage. It continues to allow a greater percentage until eventually it reaches a 50/50 ratio between the two passages.

The Turbine Diverter Valve is basically a gate. There are two passages in the flange of the Turbine Diverter Valve. One passage is open 100% of the time and the other is being controlled by this gate. When the gate is closed, the exhaust that would be going into the second volute is diverted into the first volute. What this equates to is that 100 percent of the exhaust is flowing into a volute that is roughly half the size of the turbine housing area. This keeps the energy up and helps create boost pressure much lower in the RPM range.

As the boost pressure builds, the Turbine Diverter Valve starts to move and directs some of the exhaust into the second volute (this starts to happen around 12 psi). The valve continues to open until around 22 psi when the valve is fully open and the exhaust is flowing equally through both volutes.

How Difficult Is It To Install?

The Turbine Diverter Valve is fairly easy to install as it just bolts between the turbocharger and the exhaust manifold(s). Unfortunately, even though they have made the valve 2.5 inches thick, this does move the charger and you have to adjust your piping. However, this isn’t such a bad trade off for an improvement in driveability and performance.

Proof Is In The Pudding

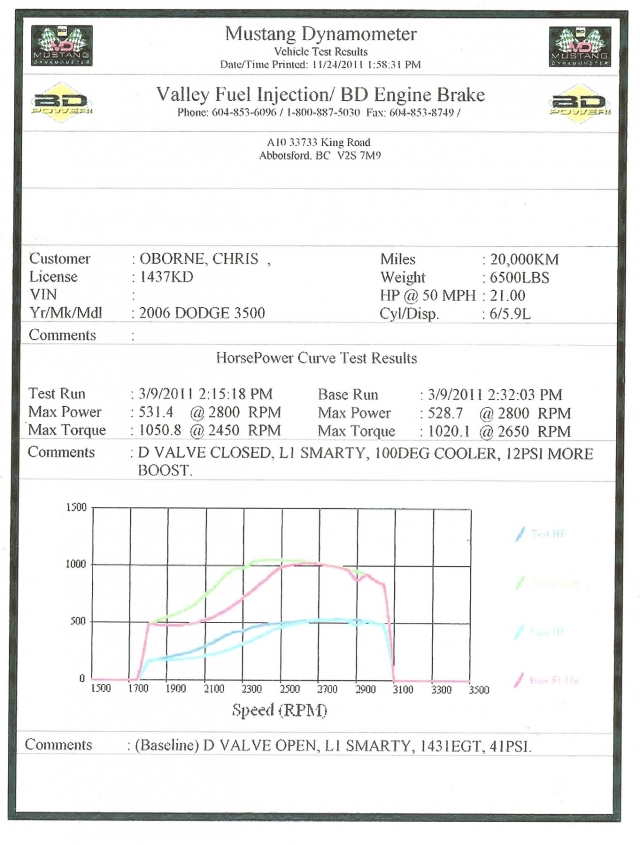

In testing, the Turbine Diverter Valve has shown the ability to get larger turbochargers to spool much quicker. In fact, there is a substantial increase in torque and a moderate increase of horsepower between 1,800 rpms and 2,500 rpms. In addition, the top end HP will also increase because the larger A/R turbine housing flows better.

If you look at this dyno sheet there is a tremendous story to be told here. While the top end power doesn’t significantly increase (Makes sense right? When the Diverter Valve is open, it is like it isn’t there), there are HUGE gains from 1800 hp all the way to 2500 RPMs. Roughly, 320 ft.lbs more torque and about 130 more horsepower in the low to mid rpm range. This is where 80 percent of your daily driving takes place!

For those that drive big single chargers on the street and strip, this is the critical RPM range that you are probably having issues with. The engineers at BD Diesel Performance have been able to achieve their goals of better low-end performance and gain top-end power.

We spoke with Brian Roth, President of BD Diesel Performance about their Turbine Diverter Valve. “What we found is that guys were having to put on a .90 A/R ratio on the turbine housing to spool their turbochargers and then they would have to put a lot of fuel in or even use nitrous to spool their turbo right at the line [for drag racing]. What will happen is we can put a Turbine Diverter on there. We can put on a bigger A/R ratio, we can go to a 1.1 or a 1.0 if they really want that bottom-end, and we can spool the turbo. The big benefit of that is that at the top RPM the larger turbine housings will develop more power because otherwise you are choking the engine. So, you get the benefit at the bottom-end by having quicker spooling turbo. At the top-end you won’t be chocking your engine because of the small turbine housing that you need because you don’t have the Turbine Diverter.”

We spoke with Brian Roth, President of BD Diesel Performance about their Turbine Diverter Valve. “What we found is that guys were having to put on a .90 A/R ratio on the turbine housing to spool their turbochargers and then they would have to put a lot of fuel in or even use nitrous to spool their turbo right at the line [for drag racing]. What will happen is we can put a Turbine Diverter on there. We can put on a bigger A/R ratio, we can go to a 1.1 or a 1.0 if they really want that bottom-end, and we can spool the turbo. The big benefit of that is that at the top RPM the larger turbine housings will develop more power because otherwise you are choking the engine. So, you get the benefit at the bottom-end by having quicker spooling turbo. At the top-end you won’t be chocking your engine because of the small turbine housing that you need because you don’t have the Turbine Diverter.”

For competition only vehicles this new technology makes it possible to run larger chargers than they were running before, with better low-end performance that the smaller turbo. What, this also means is that a higher stall or looser torque converter isn’t needed to get on boost at the line. To anyone that has been around turbochargers for any amount of time, that seems completely backwards; larger charger with better low-end performance? But it is true.

The Turbine Diverter Valve will allow people to run a properly sized charger for the top-end performance, which results in lower EGT’s (who doesn’t like that), lower drive pressure, more horsepower, and less wasted fuel out the tailpipe.

A lot of pullers are forced to run smaller turbine housings than what their top-end power needs because they can’t get the chargers to spool up. Thanks to the Turbine Diverter Valve, pullers are able to upsize their turbine housings as well as their turbine wheels to free up more horsepower.