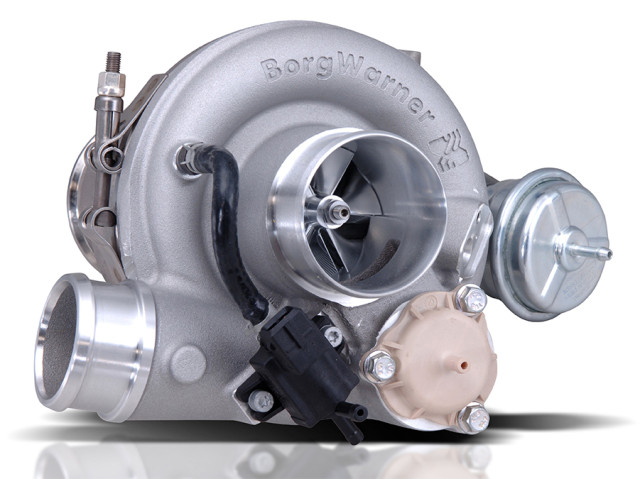

What happens when one of the largest manufacturers of turbochargers in the world builds a turbocharger for the performance market with virtually no constraints? EFR Series, or Engineered For Racing happens!

BorgWarner’s new line of high-performance turbochargers is specific to the automotive aftermarket. Traditionally, aftermarket turbochargers are “pieced” from current product lines that serve the automakers. The primary reason is cost, as it’s extremely expensive to design, test and manufacture a turbocharger from a “clean sheet.” So, companies usually leverage current inventory to make a new turbos specifically for the aftermarket, and then call it a day. The new EFR product line has no ties to the OEM market. In fact, BorgWarner could maximize this technology and feed it into production vehicles. When engineers developed EFR, they listed features they thought would be cool, might be possible, and all the performance elements customers wanted in a turbocharger. When all was said and done, they achieved about 90% of the list.

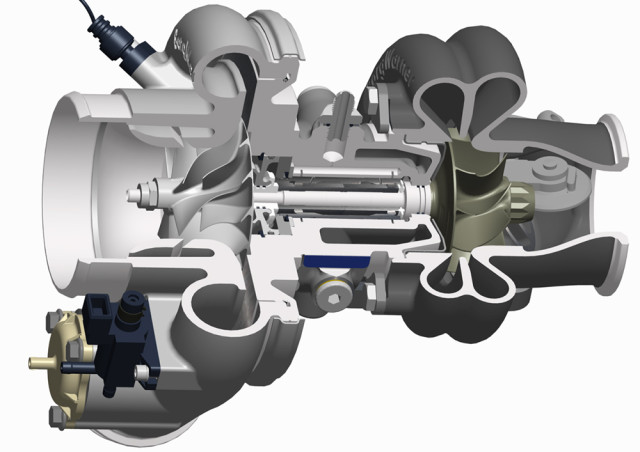

This is a cutaway CAD model of one of the EFR turbochargers. On the shaft, notice the two sets of bands on each end to seal better. These chargers, also, feature dual ceramic ball bearings and the center section has a huge cavity for cooling (optional for the steel center section, required for the aluminum bearing housing).

So, what is “amazing” about these new turbochargers?

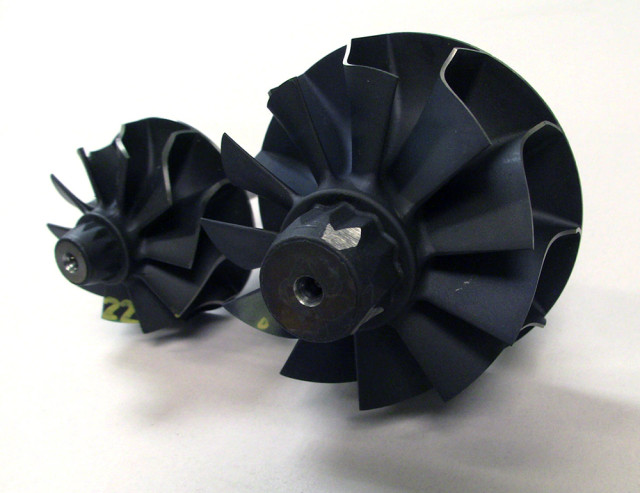

There are a number of key features but most impressive is the turbine wheel. Turbochargers are an exhaust driven device; no exhaust = no boost = no power. “The most exciting technology in the EFR package is the turbine wheel material,” says Brock Fraser. “The wheels are made from titanium aluminide. It’s not the first time this material has been used, but it’s the first time that it has been offered to the public across a range of size options.”

The Gamma-Ti turbine wheels will gain ductility with temperature and they are extremely light. This combination results in a very durable turbine wheel. Lower Right: This picture was taken during the 175-hour thermal durability test BorgWarner performs on its turbochargers.

What is Titanium Aluminide?

Titanium Aluminide or Gamma-Ti is an odd material. From a chemistry standpoint, it is an intermetallic compound, which means it isn’t a ceramic or metal.

Titanium Aluminide or Gamma-Ti is an odd material. From a chemistry standpoint, it is an intermetallic compound, which means it isn’t a ceramic or metal.

“The technical advantage is very simple: low inertia. Since Gamma-Ti has roughly one-half the weight of a typical turbine wheel, the reduction in inertia is substantial,” explains Fraser. “The turbine wheel is very light – it is nearly the same weight as the compressor wheel that is on the other end of the shaft. When paired with the ball bearing system and efficient aerodynamics, it yields a turbocharger that has no rivals in terms of boost response.”

The Gamma-Ti is used in ultra-high-end turbochargers reserved for extreme racing or other niche markets. BorgWarner overcame numerous hurdles in offering an entire product range with this tempermental material. Gamma-Ti is exceptionally difficult to cast into an intricate shape like a turbine wheel, and it’s also very challenging to attach the shaft.

Keep It Spinning

The Gamma-Ti turbine wheels are paired up with a new bearing system for BorgWarner.

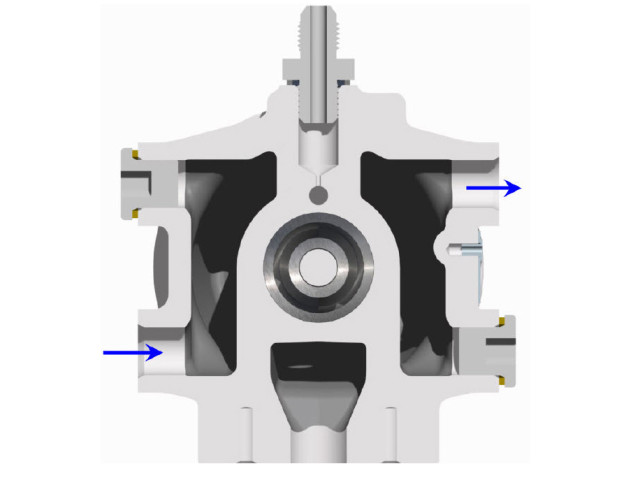

The Gamma-Ti turbine wheels are paired up with a new bearing system for BorgWarner.

“We recognize the benefits of building boost quicker and having torque response that feels tightly linked to throttle movements,” says Fraser, noting the arrangement is a dual ceramic ball bearing system.

BorgWarner designed every aspect of the new EFR line to meet its OEM requirements, using high-grade M50 races with metal cages.

“The ball bearing is much better at surviving abuse such as compressor surge, marginal oil quality, low oil pressure, and harsh acceleration,” says Fraser. “The thrust capacity of a ball bearing is believed to be about 10 times that of a conventional thrust bearing but to be honest, we don’t know the exact figure because our thrust load test rig cannot currently develop enough force to overload one. We do know that it has at least five times the capacity. Unlike the conventional system where higher axial load capacity comes at the expense of friction losses, the thrust capacity of a ball bearing is “nearly free,” by comparison, when it’s not heavily loaded.”

(Top) Pictured are the individual components that make up the bearing assembly. (Left) Notice the size difference in the EFR Bearing system compared to a competitor. (Right) Here is the same competitor's bearing system disassembled showiplastic components.

Art on the Compressor Side

In addition to the bearings, BorgWarner also looked at how the shafts seal against the housings. “Our EFR bearing system includes the latest in sealing technology, improving both resistance to oil leakage at light loads and intrusion of boost and exhaust pressures into the bearing housing while under heavy loads,” says Fraser.

The black doted line represents a standard compressor wheel outer diameter. BorgWarner uses Extended Tip Technology (shown in red) to get a smaller wheel to perform like a larger wheel.

While the turbine wheels may boast the most exciting technology of the new EFR line, the new forged milled compressor wheels can be described as artistic gems. The entire EFR line uses forged milled compressor wheels because according to Fraser, they offer a tremendous strength advantage over cast or just milled bar stock (commonly referred to as billet) wheels. The forging process keeps the grain structures intact while strengthening them as they are deformed. This additional strength comes into play at higher boost pressures where the blades are under tremendous stress.

In addition to the strength characteristics, the wheels feature BorgWarner’s Extended Tip Technology. This feature amplifies the boost pressure and flow capabilities for a given wheel size. The compressor wheels are offered with a 49 mm inducer (62 mm OD) up to a 68 mm inducer (91 mm OD). This range of wheels will support 200 to 1,000 horsepower per turbocharger.

Cover

Having a compressor wheel spin in free space doesn’t create any boost. So, a compressor cover is required to allow air in and keep it contained in the housing, thus creating boost pressure. While the basic shape of the EFR scroll is the same, they have been treated to some OEM-type upgrades.

Integrated CRV’s (compressor recirculation valves) are somewhat common among modern production turbos but are uncommon in aftermarket turbos because most use legacy compressor covers. It’s a very functional part that has a proven track record on millions of turbos and has long service life. As such, it was adopted into the EFR Series feature package.

“The CRV vents boost quickly and efficiently when the throttle closes, and it is internally-recirculated to keep turbo speed high during the shift and to keep engine control systems satisfied, especially those with a MAF sensor,” explains Fraser.

The recirculation valve is a feature of convenience but isn’t required. While all compressor covers in the EFR Series have the CRV feature cast into the cover, there are block off plates available.

Another useful feature on EFR cover is a pre-drilled hole and pad that allows the installation of a speed sensor. Typically, if you wanted a speed sensor, you would have to send your compressor cover off to a machine shop and have a very precise hole drilled to make sure everything was at the right angle for the sensor to pick up wheel rotation. The BorgWarner hole on the pad is pre-drilled about 90 percent through. A quarter-inch drill is needed to finish the hole. No other measurements are required, as all of the precision is built into the cover. Those not running a speed sensor don’t have to plug up the hole, since it’s not fully open.

(Top Left) A standard drill bit is all that is needed to add a speed sensor. (Top Right) Every compressor cover is pre-drilled if you want to add a speed sensor. (Lower Images) The compressor covers are all pre-machined with a hose barb and a V-band flange. If you want to use the v-band, just cut the hose barb off. No need to send the compressor cover out to get it machined.

Finally, the EFR compressor covers offers a dual-outlet option that is designed for both a hose or V-band connection. That means no worries over special orders or if turbo in stock at the retailer will work on your application, as it can adapt to either connection.

Bearing housing

There are two bearing housings available for the EFR line. Many BorgWarner bearing housings are cast iron, but developed through its official participation in the IndyCar series is an aluminum bearing housing. The aluminum housings require water-cooling, which is also strongly recommended for the cast-iron housings.

(Top) The bearing housings are pre-tapped to accept cooling in from either side as well as coolant out. All that is required is a cross flow pattern. (Bottom) The oil drain is machined for a standard drain flange as well as tapped for an NPT fitting.

For cooling, there are two options with the housings machined for both inlet and outlet provisions on each side. Proper cooling requires a cross flow, so the housings can be plumbed with water entering and exiting either side, as long as the cross-flow pattern is met.

To simplify the turbo installation and packaging, BorgWarner sized the oil passages for a -4AN inlet. For the oil outlet, there is the traditional two-bolt flange, and the drain is premachined with 3/8 NPT threads so a fitting can be used. BorgWarner recommends a 3/8 NPT to -8AN fitting for most applications.

As mentioned earlier, the housings have been designed for a better sealing solution. The dual seals offer about 50 percent reduction of blow-by.

“This sealing system along with the extended bearing span (for added stability) does make the center section long, and is the only drawback of the EFR internal component selections. This is a clear example of priorities: function and durability comes first,” says Fraser.

Turbine Housings

All of the turbine housings are cast out of stainless steel, which according to BorgWarner, is extremely crack-resistant and has much better strength properties at high temperatures than cast iron. In addition, stainless steel is naturally corrosion-resistant. So, these housings will perform better, look better, and last longer than traditional housings.

There are seven different sizes of turbine housings available for the six different wheels that make up the current EFR line. Of these, the 49 and 54 mm inducer compressor wheels are for smaller engines than we cover. Same with the 0.64, 0.85, and 0.80 A/R turbine housings. For our purposes, there are four A/R’s for the four compressor wheels that we are going to focus on.

Turbine Housing Lingo

Wastegates can be classified as single scroll and twin scroll. This refers to the number of passages that make up the volute. Generally, two scrolls will help spool up a charger quicker under low to medium RPM range. The benefits decrease with higher rpm.

A/R; stands for area divided by radius. This number helps to identify the size of the turbine housing. The radius is taken from the center of the wheel out to the centroid of the volute near the housing’s tongue section. Contrary to popular belief, the A/R is not constant throughout the scroll. Area decreases while continuing to traverse the volute, while centroid radius changes very little.

The last common number that you will see on a turbo is a T3, a T4, or something along those lines. This refers to the flange geometry of the turbine housing inlet. These are common and interchangeable in the turbocharger industry.

For the wastegated housings, BorgWarner made huge strides and improvements to the traditional wastegated housings. Traditionally, turbochargers are pieced together from what is currently available in the OE market. This means that most wastegated housings are designed for diesels that run high boost pressures. So, the wastgates don’t need to be very large to vent off the excess drive pressure. Over the years, the aftermarket has developed the abilities of the “off the shelf” wastegate options and it is extremely common to see aftermarket standalone wastegates plumbed inline of a turbocharger.

“As part of our ‘clean sheet’ approach, we wanted to make internal wastegates that were capable of handling the flow requirements of high performance applications,” says Fraser. “This meant very large valve sizes (36 mm and 42 mm valve head) and aerodynamically-efficient porting. When you look at these designs, you won’t see harsh corners, fabricated edges, or other losses. When as much as 40 percent of the flow needs to pass through the wastegate at maximum power, a flow-optimized solution is needed.”

So, the optional wastegated housings are the 0.83 A/R Single Scroll T3 and the 0.92 A/R Twin Scroll T4. These housings have the 42 mm valve which translates to a 36 mm port size. (Keep in mind that external wastegates are identified by valve size, not port size too). To ensure that the wastegates are easy to tune, BorgWarner offers very long actuator stroke lengths and multiple versions of wastegate actuator. Each actuator is adjustable over a wide range using common hand tools with no need for disassembly.

The IndyCar spec turbocharger uses the off the shelf aerodynamic package that is available for everyone.

The Results?

How good are these chargers? They are almost identical to the turbos used in the IndyCar series. The only exception is that the inlets and outlets are unique to Indy because those cars are exceptionally sensitive to weight and packaging space. The compressor wheels, turbine wheels, bearings, etc., are the same as what IndyCar is using. So, this off the shelf turbocharger that is available to you is also used in one of the most demanding motorsports venues.