The recall involving GM’s 10-speed automatic transmissions, specifically the units branded as “Allison” in heavy-duty trucks, has become one of the most controversial issues facing diesel pickup owners in recent memory. At the heart of the situation is a potentially catastrophic defect that can cause the rear axle to lock up while driving, posing serious safety risks.

But what’s drawing even more attention isn’t just the defect itself, it’s how General Motors has handled the issue, and the claims that a proven mechanical fix already exists, developed by a small transmission engineering company, yet allegedly ignored by GM for over a year.

The Background: A Dangerous Recall With No “Fix”?

In late 2024, General Motors issued a recall (NHTSA #N242454440) covering over 462,000 vehicles, warning owners that a failure in the transmission could cause the rear axle to seize while in motion.

GM’s official response included a software update designed to detect the issue early and place the vehicle into a “failsafe mode” to prevent axle lockup. However, according to Next Gen Drivetrain, an independent drivetrain engineering company, this software update doesn’t address the core issue, it only masks the symptoms. Even more concerning, they claim GM has denied the existence of a permanent mechanical fix, despite being offered one as early as January 2024.

Enter Next Gen Drivetrain: The Engineers Claiming to Have the Solution

Based in the U.S., Next Gen Drivetrain specializes in re-engineering transmission systems, including GM’s 10-speed units. The company reports that they began fielding customer complaints about mysterious transmission lockups in mid-2023, long before GM formally acknowledged the problem.

By conducting extensive testing, data logging, and valve body disassembly, Next Gen’s engineers claim to have traced the problem to a hydraulic issue inside the valve body. Their research suggests that a worn or defective valve body can cause an extra clutch pack to engage under load, locking the output shaft—and with it, the rear axle.

What’s more, they report a 100-percent success rate in fixing affected trucks using their in-house engineered Project Carbon Valve Body Upgrade Kit or their fully rebuilt valve bodies, both of which are sold directly to consumers and shops across the U.S.

What’s Going Wrong Inside the Transmission?

Unlike older transmissions that used bands or servos, GM’s 10-speed unit relies solely on six clutch packs—two brake clutches and four rotating clutches. Under normal operation, three clutch packs engage at a time to transmit power. If only two engage, the vehicle is effectively in neutral. But if four engage at once, the transmission enters two gears simultaneously, binding up the drivetrain.

Next Gen’s internal analysis found that hydraulic crossleaks within the second-generation GM 10-speed valve body could cause a fourth clutch pack to engage at inappropriate times. This leads to sudden and total drivetrain lockup, a condition confirmed by numerous customer complaints and video footage.

Their conclusion? The issue is mechanical, not electronic, and worsens with wear.

The Smoking Gun: Ford’s Transmission Doesn’t Have This Problem

Interestingly, Ford’s version of the 10-speed transmission—also derived from the same basic design—does not exhibit the same catastrophic failures. Neither does GM’s first-generation 10-speed transmission.

Next Gen identified that the second-generation GM valve body deviates from both of those versions. And in their testing, all failures were linked to second-generation valve bodies, whether in GM-branded units or the rebadged “Allison” versions.

Dealership Frustration and Consumer Fallout

According to the company, some GM dealerships recognized the issue early and purchased Next Gen’s parts out-of-pocket to repair customer vehicles, as GM reportedly refused to cover the repairs—even when offered discounted parts.

This situation has created widespread frustration among consumers, many of whom are left without loaner vehicles and are facing extended downtimes. For business owners who rely on their trucks for work, this has had significant financial consequences.

How to Tell If a Transmission Is Already Damaged

Next Gen advises that fluid color is one of the best indicators of internal damage. Transmission fluid should be bright red. If it appears dark or murky, it may indicate substantial clutch wear, signaling the need for a full transmission upgrade.

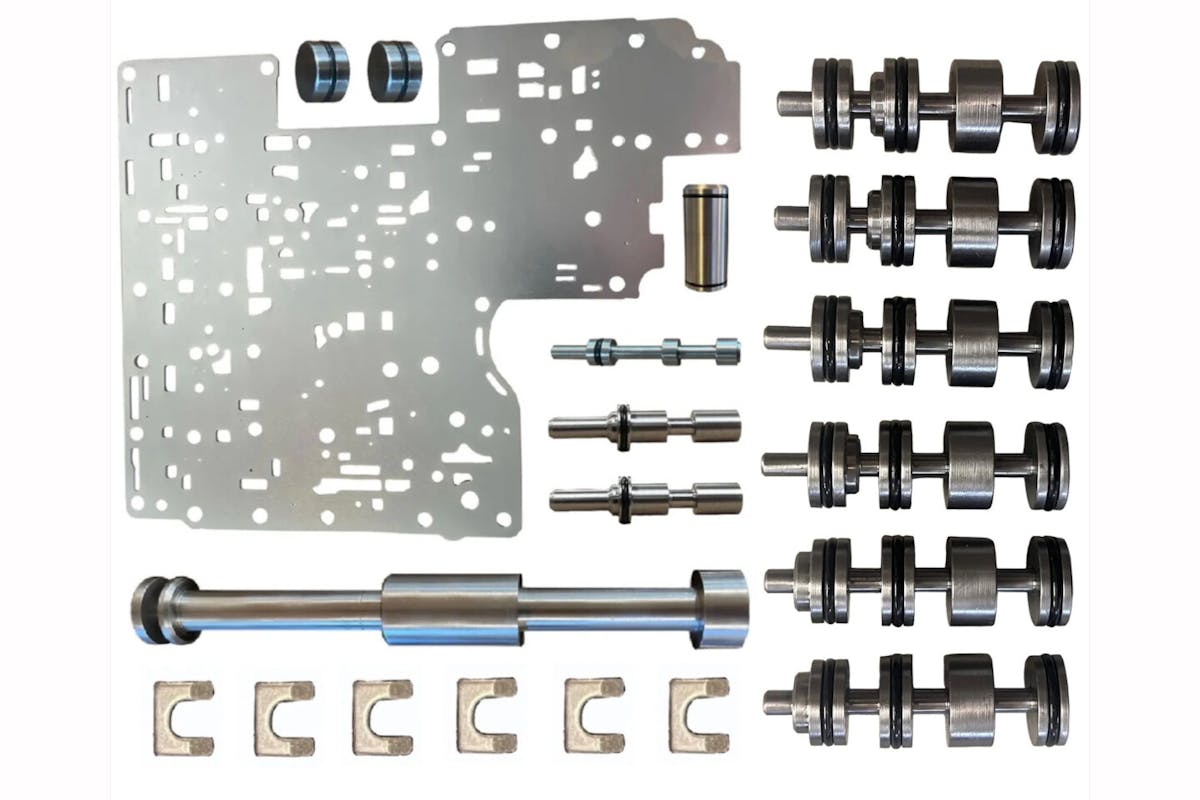

For trucks with clean fluid, a valve body upgrade may be all that’s needed. Next Gen offers a DIY valve body upgrade kit, which includes billet valves, a modified separator plate, and other upgraded components designed to correct the failure points. For more heavily used trucks or those experiencing repeated issues, they recommend their fully rebuilt valve bodies, which also include new electronics.

When a New Transmission Is Needed

For trucks with significant damage, Next Gen also offers complete upgraded transmissions built from the ground up with their proprietary parts, parts that are not available to mainstream rebuilders.

They caution consumers to avoid cheap rebuilds or “updated” OEM valve bodies, citing numerous cases of premature failure after only a few thousand miles. In one documented case, a customer returned a “built” $6,500 transmission that failed again after just 3,000 miles due to the same underlying issue.

The Software Update Isn’t Enough

GM’s official stance is that a software patch can reduce the risk by placing the vehicle into limp mode before a lockup occurs. But Next Gen argues that this is a stopgap measure at best. Their position is clear: the root cause is mechanical, and only a mechanical solution will prevent the problem from recurring.

Their findings suggest that GM’s “updated valve body” does not contain significant changes to prevent the failure. After disassembling a unit, Next Gen concluded that the revisions were nominal and unrelated to the cause of the failure.

A Call for Transparency—and Action

The most serious accusation from Next Gen Drivetrain is that GM has known about this fix for over a year and actively chosen not to implement it. Whether due to cost, liability concerns, or internal politics, the company claims GM has opted to deny, downplay, or obscure the existence of a real solution.

Yet, the stakes are high. GM trucks, especially heavy-duty diesel models, are often $80,000–$100,000 investments. Leaving customers in the dark, while knowing a proven fix exists, raises ethical and legal questions that are sure to continue generating scrutiny.

Final Word: An Issue That Demands Accountability

As of mid-2025, Next Gen Drivetrain continues to support GM truck owners affected by the 10-speed failure. Their staff are reportedly trained specifically on this recall, and they provide both parts and technical support directly to customers and repair shops.

For truck owners facing axle lockup issues, or anyone affected by the #N242454440 recall, Next Gen positions itself as a reliable alternative to OEM solutions, claiming both the experience and engineering to back their fix.

You might also like

2500 Versus 3500: How Much Heavy Duty Beef Do You Actually Need?

A common question is whether to buy a 2500 or step up to a 3500 heavy duty truck: 2500 versus 3500. Let's work through the decision process.